Welcome To Know Our Products, We Can Offer You High Quality Products!

WhatsApp / WeChat : 008615127880005

Email : info@aocno.com

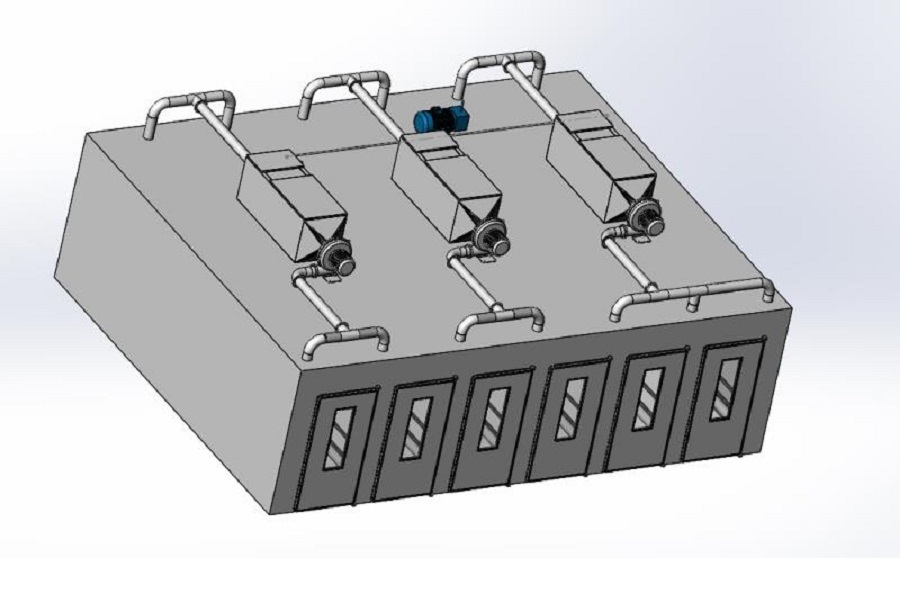

High Precision Dough Divider

AOCNO

Product introduction

In the modern food industry, accurate dough division is crucial to ensure the quality and production efficiency of products such as bread and pastries. In order to meet the growing market demand, High Precision Dough Divider came into being and became one of the core equipment for bakeries, food processing plants and baking production lines.

What is High Precision Dough Divider?

High Precision Dough Divider is a device specially used to divide dough evenly into multiple small portions. It is widely used in the production of bread, buns, dumplings, pastries and other foods. Compared with the traditional manual division method, High Precision Dough Divider can provide more precise weight control and more consistent division effect, significantly improve production efficiency, and reduce errors and waste caused by manual operation.

Technical advantages of High Precision Dough Divider

1. Accurate division: High Precision Dough Divider adopts advanced automation technology, which can divide dough into multiple portions of precise weight according to the set parameters to ensure that the weight of each portion of dough is consistent. Whether it is mass production or small batch customization, high precision can maintain consistency, avoiding problems such as uneven weight and different specifications that may occur in traditional segmentation methods.

2. Improve production efficiency: The high-speed operation and automated operation of the equipment make the dough segmentation process more efficient and save a lot of manual time. Compared with traditional manual segmentation, the High Precision Dough Divider not only greatly improves the segmentation speed, but also reduces the errors in manual operation and reduces waste in production.

3. Reduce human interference: Manual segmentation of dough is easily affected by the skills and fatigue of the operator, resulting in product instability. The High Precision Dough Divider can output stably to ensure that each segmentation meets the standards, and can maintain high consistency regardless of the operator's experience.

4. Automated control and intelligent management: The modern High Precision Dough Divider is equipped with an intelligent control system with a simple and intuitive operation interface, which can quickly set and adjust segmentation parameters. In addition, the intelligent management system can monitor the production status in real time, automatically detect equipment failures, and promptly alarm, reducing the impact of equipment failures on production progress.

Market application of High Precision Dough Divider

1. Bread and pastry production: In the bread and pastry industry, High Precision Dough Divider can accurately divide the dough according to different recipes and product requirements, ensuring the consistency of the weight of each portion of dough, improving the consistency of the appearance and taste of the product, and reducing the waste of raw materials.

2. Steamed buns and dumplings manufacturing: In the production of traditional Chinese food, the accuracy of dough division is crucial. High Precision Dough Divider can divide the dough into uniform small portions, ensuring that the taste and appearance of products such as steamed buns and dumplings are more uniform, improving production efficiency, and reducing the tediousness of manual operation.

3. Other food processing: In various food processing fields that require dough division, such as pizza, pie, etc., the use of High Precision Dough Divider can not only improve production efficiency, but also ensure the stability of food quality and meet different specifications and quality requirements.

Advantages of High Precision Dough Divider

- Improve product consistency: High Precision Dough Divider ensures that the weight and size of each dough segment are consistent, reducing the differences caused by manual operation, thereby improving the consistency and quality of the final product.

- Reduce production waste: Through precise segmentation, dough surplus and waste are reduced, helping companies to reduce raw material costs while improving production efficiency.

- Save labor costs: Automated equipment replaces a large number of manual operations, reducing manpower requirements, and companies can invest more resources in product research and development and market expansion.

- Improve production flexibility: High Precision Dough Divider can adjust segmentation parameters according to different needs, adapt to different types of production tasks, and make the production line more flexible.

Future Outlook

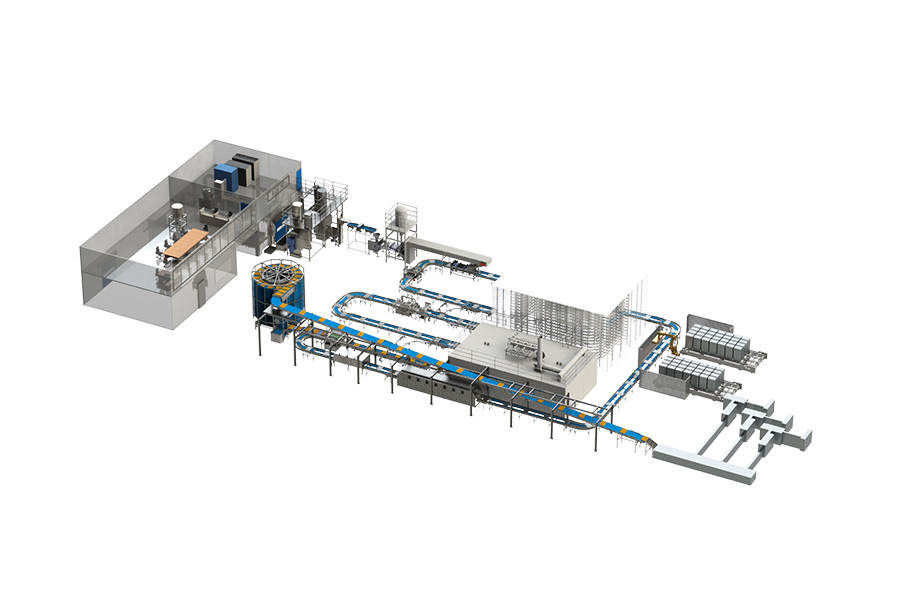

With the continuous development of the food industry and the increasing market demand for high-quality and efficient production, High Precision Dough Divider will continue to develop in the direction of intelligence and automation. Future equipment will pay more attention to integration with production lines, providing more accurate and efficient solutions to meet personalized and customized production needs.

Conclusion

As an important part of modern food processing equipment, High Precision Dough Divider is increasingly becoming a key tool to improve production efficiency and ensure product quality. With the continuous advancement of technology, it will show great potential and application value in more fields, helping enterprises stand out in the fiercely competitive market.

AOCNO high-precision dough divider can efficiently segment toast, hamburger, hot dogs, and pizza dough. Vector technology metering pumps improve dividing.

Innovation technology multiple patents:

Accuracy: Advanced screw vector extrusion technology and advanced dough segmentation machine achieve the most accurate cutting, with an accuracy deviation of no more than 1%.

Efficiency: The maximum running speed during cutting can be up to 100 cuts per minute.

Voltage: 220/380V Range: 50/60Hz

Characteristics: Vector screw extrusion technology improves product uniformity, low maintenance rate, and maintains high-precision cutting throughout the 15 year lifespan of the machine.

Quality: No need to oil, reducing operating and cleaning costs. Efficient design, fewer moving parts, and lower total maintenance costs. The vacuum exhaust soft extrusion technology enhances the extensibility of the dough, expels the fermented gas, generates new gas, and enhances the bread flavor.

Parameter:

| Model | Power | Range | Number of divided dough | Maximum divided weight |

| ACN-VE800 | 7.5kW | 25-300g | 100pcs/min | 800kg/hour |

| ACN-VE1200 | 9kW | 30-400g | 100pcs/min | 1200kg/hour |

| ACN-VE1600 | 12kW | 40-500g | 100pcs/min | 1600kg/hour |

| ACN-VE2400 | 15kW | 100-1000g | 75pcs/min | 2400kg/hour |

| ACN-VE3600 | 22kW | 200-1500g | 75pcs/min | 3600kg/hour |

Product catalogue

AOCNO 2024 product catalogue

2024/06/20

File format:

File size:

2.3MB

Company workshop

ONLINE CONSULTING