Welcome To Know Our Products, We Can Offer You High Quality Products!

WhatsApp / WeChat : 008615127880005

Email : info@aocno.com

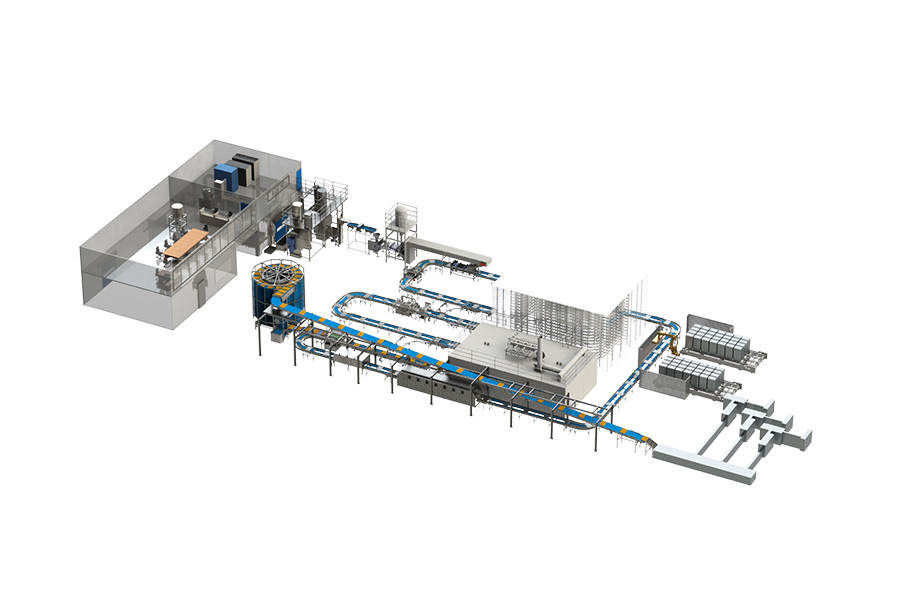

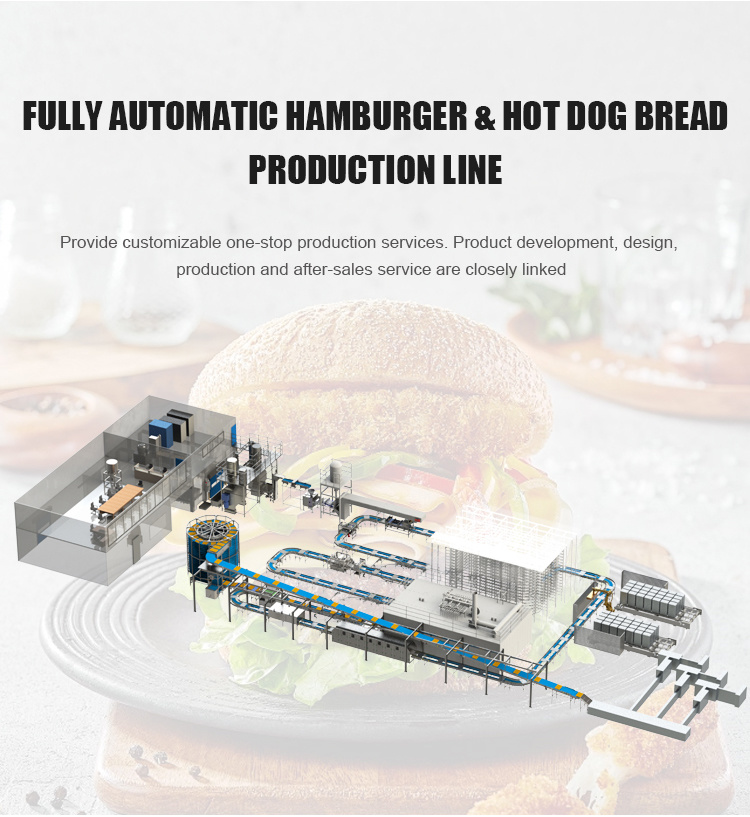

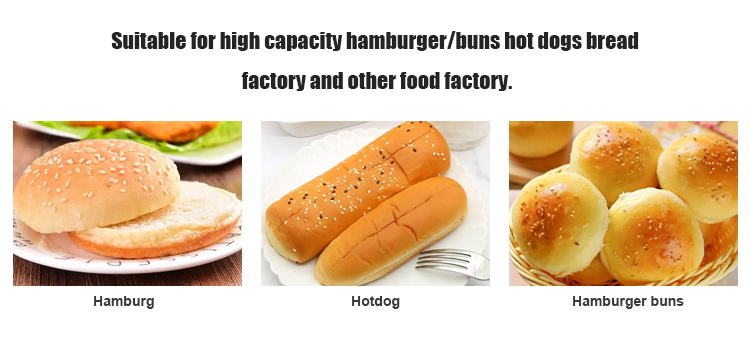

Automaitic Hamburg&Hot Dog Production Line Bake Factory Equipment

AOCNO

Product introduction

1、Automatic ingredient system

2、Mixing system

3、Dough pump and dough conveyor

4、Dough divider

5、Belt frozen rounder

6、Intermediate proofer

7、Multifunctional moulder

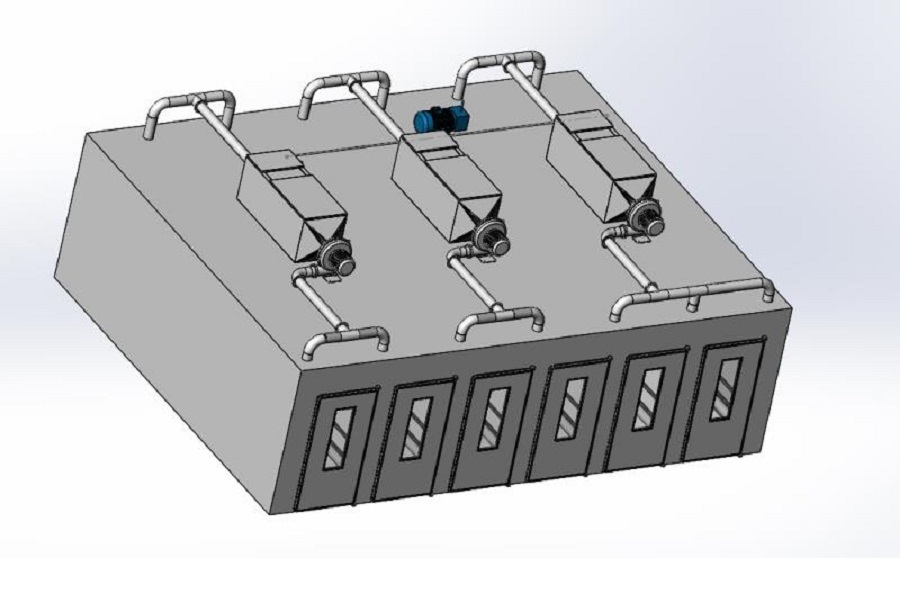

8、Centralized multi-channel powder harvester

9、Panner

10、Servo shaker

11、Pan conveyor

12、Continuous proofer

13、Water splitter

14、Glazer

15、Sesame seed sprinkler

16、Continuous oven

17、Continuous depanner

18、Pan cleaner

19、Pan cooler

20、Spiral cooling tower

21、Robot pan stacker/ unstacker system

22、Pan inverter

23、Bread conveyor

24、Auto slicer

25、Auto bagger

26、Ink jet printer

27、Metal detector

Production Capacity: 6000-36000 pcs / h

Customized according to customer demand

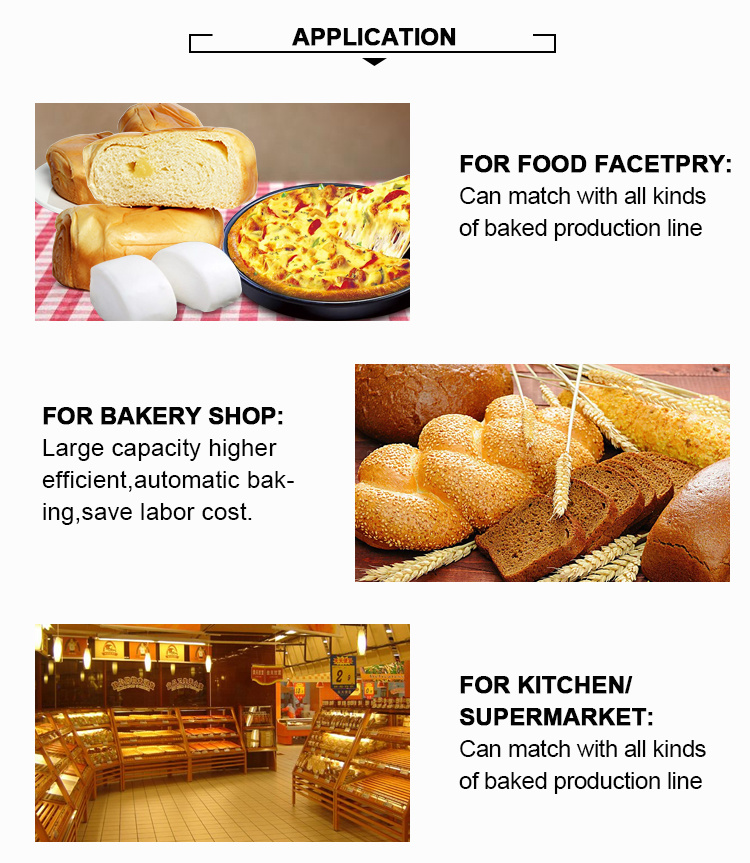

Bakery equipment plays a pivotal role in the success of bakery businesses, enabling efficient production processes, consistent quality, and diverse product offerings. From mixers and ovens to dough dividers and proofing cabinets, modern bakery equipment combines innovation, precision, and reliability to meet the demands of today's dynamic baking industry. Let's explore the remarkable features, benefits, and wide-ranging applications of state-of-the-art bakery equipment.

-

Advanced Technological Features: Cutting-edge bakery equipment incorporates advanced technological features that streamline bakery operations and enhance productivity. Automated controls, programmable settings, and intuitive interfaces simplify operation and allow for precise adjustments, ensuring consistent results with every batch. Additionally, equipment with smart connectivity enables remote monitoring, maintenance tracking, and data analysis for optimized performance.

-

Efficient Production and Time Savings: Bakery equipment is designed to optimize production efficiency, allowing bakers to meet high demand while reducing labor-intensive tasks. High-capacity mixers with variable speed controls ensure thorough mixing, saving time and effort. Automated dough dividers accurately portion dough, eliminating manual weighing and shaping. Energy-efficient ovens with even heat distribution promote faster baking cycles, increasing output and reducing overall production time.

-

Consistent Quality and Product Uniformity: Precise temperature control, timed cycles, and uniform heat distribution in bakery equipment contribute to consistent quality and product uniformity. This consistency is crucial for bakery businesses aiming to deliver delectable bread, pastries, and cakes that meet customer expectations. Whether it's achieving consistent dough texture, uniform baking results, or perfectly proofed products, modern bakery equipment delivers reliable outcomes time after time.

-

Versatile Applications and Diverse Product Offerings: Bakery equipment caters to a wide range of applications, allowing bakeries to diversify their product offerings and cater to varying customer preferences. Equipment like dough sheeters facilitates the production of laminated pastries, while specialized attachments enable the creation of custom-shaped bread or decorative cake designs. With adaptable equipment, bakeries can expand their menus, experiment with new recipes, and meet evolving market trends.

-

Enhanced Food Safety and Hygiene Standards: Bakery equipment adheres to stringent food safety and hygiene standards, ensuring the production of safe and sanitary baked goods. Materials such as stainless steel, resistant to corrosion and easy to clean, are commonly used in the construction of bakery equipment. Sealed controls, removable components, and built-in sanitation systems facilitate thorough cleaning, preventing cross-contamination and maintaining high levels of hygiene.

-

Space Optimization and Ergonomic Design: Bakery equipment is designed with space optimization and ergonomic considerations in mind. Compact footprint models maximize workspace efficiency, especially in smaller bakery setups. Ergonomic features, such as adjustable heights, user-friendly controls, and easy-access compartments, promote operator comfort, reduce fatigue, and enhance overall workflow.

-

Sustainability and Energy Efficiency: Many modern bakery equipment manufacturers prioritize sustainability by incorporating energy-efficient technologies and practices. From energy-saving ovens with improved insulation to eco-friendly proofing systems that minimize energy consumption, bakery equipment helps reduce the environmental impact of bakery operations while keeping operating costs in check.

In conclusion, cutting-edge bakery equipment revolutionizes bakery operations by combining advanced technology, efficiency, and versatility. With features that ensure consistent quality, enhance productivity, and adhere to food safety standards, this equipment empowers bakery businesses to deliver exceptional baked goods while meeting evolving market demands. From small artisanal bakeries to large-scale production facilities, investing in innovative bakery equipment is a recipe for success in the competitive baking industry.

Product catalogue

AOCNO 2024 product catalogue

2024/06/20

File format:

File size:

2.3MB

Company workshop

Click the links for more product information:

ONLINE CONSULTING