Welcome To Know Our Products, We Can Offer You High Quality Products!

WhatsApp / WeChat : 008615127880005

Email : info@aocno.com

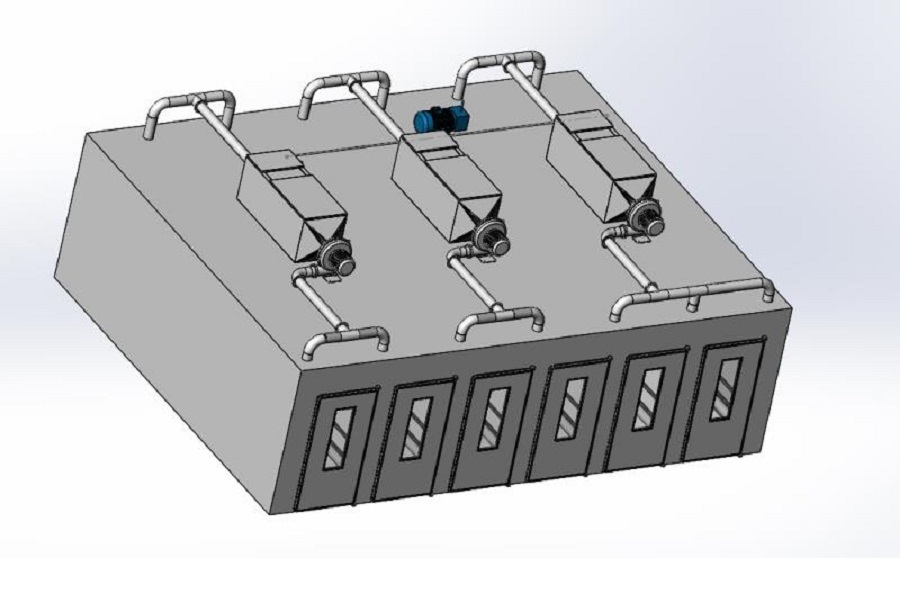

Dough Divider

AOCNO

Product introduction

In the field of integrated circuits and electronic products, some unexpected innovative ideas have recently emerged, and one of the peculiar connections is subtly related to the concept of "Dough Divider".

In the production and manufacturing of integrated circuits, we know that chip manufacturing is an extremely precise process, just like making a fine work of art. Traditionally, when designing and laying out a chip, each functional module is like a small unit waiting to be reasonably allocated resources, similar to the dough divider dividing dough into even and equal parts. For example, in a complex processor chip, the layout planning of modules such as computing units and storage units is like dividing the "dough" with different functions reasonably in the "big plate" of limited chip space. Researchers have found that by borrowing the concept of precise and balanced allocation of Dough Divider, chip layout can be better optimized and the overall performance of the chip can be improved.

From the perspective of electronic products, today's electronic devices pursue miniaturization and multi-functionality. Take smartphones as an example. The internal space is extremely limited, but it has to accommodate various chips, circuit components, batteries and other components. This requires a strategy similar to Dough Divider to reasonably divide the limited space into different components. For example, the arrangement of the positions of various chips on the motherboard must take into account both the efficiency of signal transmission and heat dissipation, just like dividing the "dough" of space into components with different functional requirements.

In addition, in the design process of circuit integration, energy distribution can also be analogized to dough division. Just like the dough divider divides the dough into portions of appropriate size, the power management module needs to accurately distribute the power to each functional circuit to ensure that each part can get enough and appropriate energy supply, avoiding the situation where one module has excess power while other modules have insufficient power, thereby ensuring the stable operation of the entire electronic product.

Although the "dough divider" was originally a concept in the field of food processing, this innovative analogy in the field of integrated circuits and electronic products provides engineers with a new perspective, and is expected to bring more efficient, compact and high-performance integrated circuit and electronic product design solutions in the future.

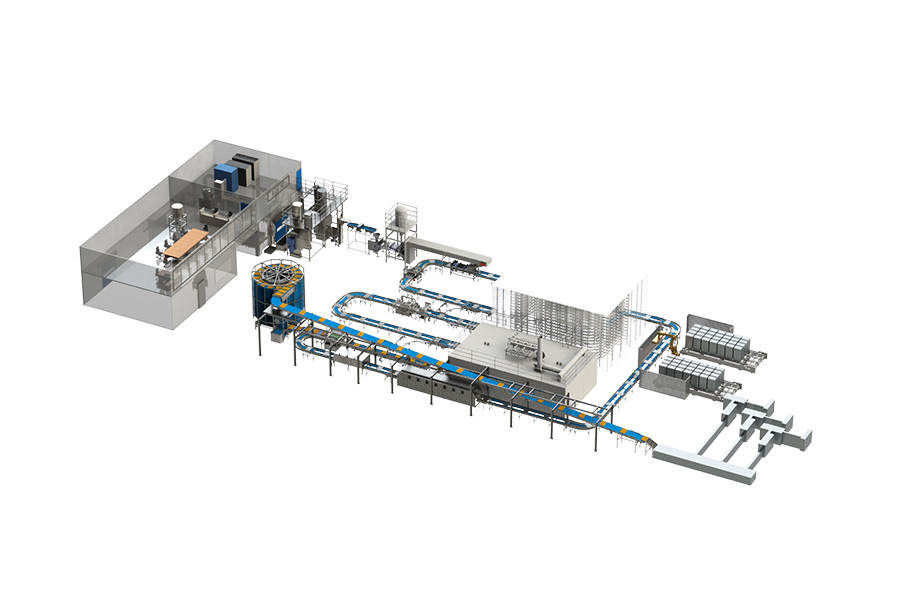

AOCNO high-precision dough divider can efficiently divide the dough of toast, hamburgers, hot dogs, and pizza.Vector technology metering pumps improve dividing.Four types of molds can be replaced, 30g-1500g

Accuracy

Advanced screw vector extrusion technology and advanced dough dividing machine to achieve the most accurate cutting, with an accuracy deviation of no more than 1%

Characteristics

Vector screw extrusion technology improves product uniformity,and maintains high-precision cutting throughout the 15 year lifespan of the machine.

Efficiency

The maximum running speed during cutting can be up to 100 cuts per minute.

Quality

No need to oil, reducing operating and cleaning costs. Efficient design, fewer moving parts, and lower total maintenance costs. The vacuum exhaust soft extrusion technology enhances the extensibility of the dough, expels the fermented gas, generates new gas, and enhances the bread flavor.

|

Model |

Power (KW) |

Range (g) |

Number of divided dough (pcs/min) |

Maximum divided weight (kg/hour) |

|

ACN-VE800 |

7.5 |

25-300 |

100 |

800 |

|

ACN-VE1200 |

9 |

30-400 |

100 |

1200 |

|

ACN-VE1600 |

12 |

40-500 |

100 |

1600 |

|

ACN-VE2400 |

15 |

100-1000 |

75 |

2400 |

|

ACN-VE3600 |

22 |

200-1500 |

75 |

3600 |

Product catalogue

AOCNO 2024 product catalogue

2024/06/20

File format:

File size:

2.3MB

Company workshop

ONLINE CONSULTING