Welcome To Know Our Products, We Can Offer You High Quality Products!

WhatsApp / WeChat : 008615127880005

Email : info@aocno.com

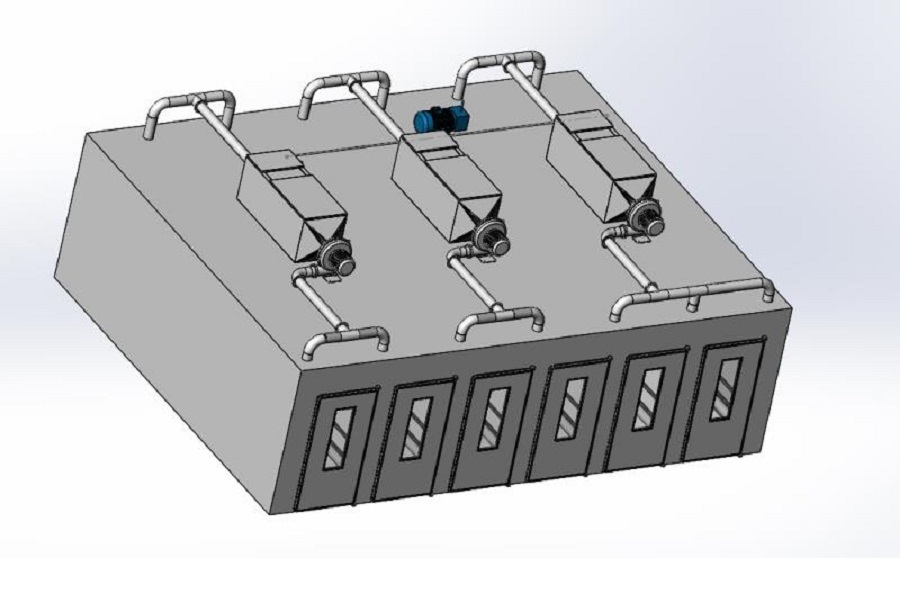

Tunnel oven

AOCNO

Product introduction

In the world of bakery and industrial baking, a variety of remarkable bakery appliances and machines play crucial roles. Let's take a closer look at some of these essentials.

The baking oven industrial is the heart of any bakery, providing the heat and environment needed to create delicious baked goods. Tunnel ovens, such as the tunnel baking oven and gas tunnel oven, offer continuous and efficient baking processes. These continous ovens ensure a smooth flow of production, allowing for large volumes of products to be baked simultaneously.

The contious baking oven is designed for consistent results and high productivity. Bakery tunnel ovens for sale provide opportunities for bakeries to invest in quality equipment to enhance their operations.

When it comes to the machine for bakery, there is a wide range available. From basic tools to advanced machinery, these bakery machines contribute to the quality and efficiency of the baking process.

Bakery equipment companies and bakery machinery manufacturers are constantly innovating and developing new technologies to meet the evolving needs of the industry. Bakery equipment company produce a diverse array of bakery equipment, including bakery tunnel oven for sale, mixers, and other essential appliances.

Among these, industrial bakery machines are specifically tailored for large-scale operations. Bakery equipment like ovens, proofers, and other appliances ensure that every aspect of the baking process is optimized.

Whether you're a small bakery or a large industrial operation, having the right combination of bakery equipment and appliances is essential for success. It allows you to create high-quality products consistently and meet the demands of your customers. The world of bakery is constantly evolving, and these tools and machines are at the forefront of that progress.

Three specifications of the tunnel oven:two pans, three pans, four pans (ultra wide).

Four model:electric radiation tunnel oven, gas radiation tunnel oven, pure hot air circulation tunnel oven, and hot air radiation tunnel oven

Baking effect:evenly colored,precise temperature control,Double -control interface, easy to use operation

Stability

The frame adopts national standard thick stainless, with a design of "external solid seal,internal freedom". The oven temperature is stable at 400℃

Security

Adopting imported combustion equipment (such as Riello and Weishaupt), every detail affecting the safety of the equipment has strict control and anti-error lock Settings.

Energy efficiency

Using high-quality insulation materials can effectively reduce the solid heat conduction of the material, more energy-efficient and environmentally friendly

Three heating methods: radiation, convection, conduction;

Stainless steel shell, and the inner cavity is aluminized plate;

The thermal insulation layer is high-density ceramic fiber insulation cotton.

Observation windows are provided on both sides for easy observation of the baking status;

Fully automatic damper control system

Features and advantages

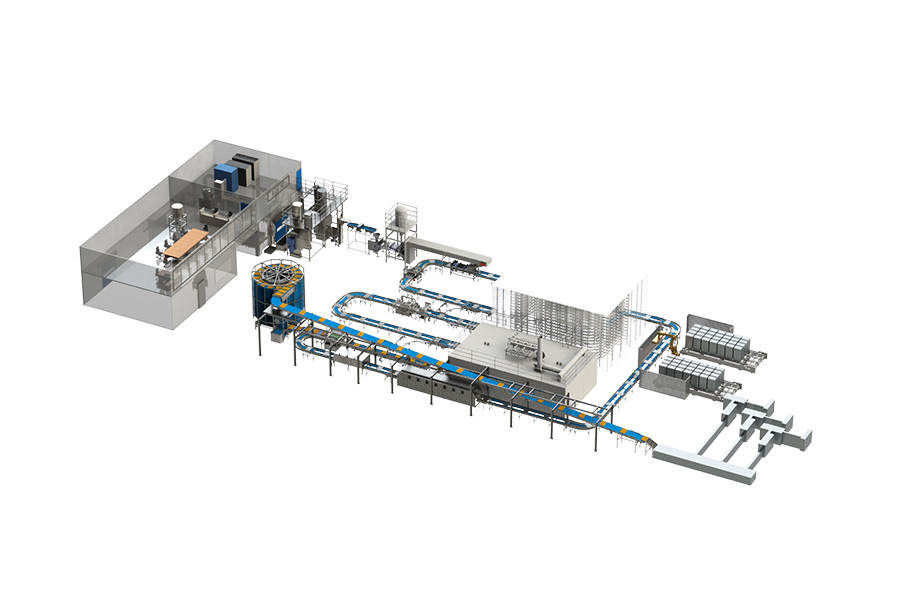

1. Save production space, reduce labor demand, and improve production efficiency.

2. The same production space and personnel can reach twice the output

3. The baked product is uniform and has no color difference

4. Adopting compressed double-layer insulation to reduce heat loss and energy consumption.

5. The same output saves 15% of energy consumption than ordinary tunnel oven;

6. Reasonably reduce the baking space ensures the heating rate during baking and reduce heat loss.

7. The baking output can be humanized adjustments according to product weight and water content, without being affected.

8. Independent temperature zone and speed control,adjust according to production requirements.

It can be equipped with automatic conveying system and automatic three-dimensional cooling production lines.

The length of the tunnel oven can be customized according to customer needs

Baking range

Bread, cake, biscuit, moon cake, pastry and other baked food.

Key components:

1 Far infrared electric heating element

2 12 inch Siemens touch screen PLC,

3. SEW reducer.

4 Siemens electrical control system

6. Stainless steel tube radiator with STIR far-infrared ceramic coating,reduces baking time by 6%. Enhance the bright color of baked goods.

Advantages:Innovative design,with radiation, convection, and conduction,3 heating methods.

With hot air circulation system, electric heating device and air convection system controlled by PID.

The oven frame is made of carbon steel, the inner chamber is made of high-temperature resistant steel, and the outer shell is made of 304 stainless steel.

Stainless steel conveyor belt.

High density ceramic fiber insulation cotton.

Quick heating,shorten the baking time

4-5 temperature control zones.

2 sets of air convection systems, 4 convection fans.

With 4-6 open observation windows.

Users can customize various width and length specifications, and the effective baking area can be customized from 9 square meters to 125 square meters

|

Specification |

Internal height |

Inner width |

Outer Height |

Tray size |

|

Two Pans |

850mm |

1400mm |

1600mm |

400*600 600*800 |

|

Three Pans |

850mm |

2000mm |

1600mm |

400*600 600*800 |

|

Four Pans |

850mm |

2650mm |

1600mm |

400*600 600*800 |

Product catalogue

AOCNO 2024 product catalogue

2024/06/20

File format:

File size:

2.3MB

Company workshop

ONLINE CONSULTING