Welcome To Know Our Products, We Can Offer You High Quality Products!

WhatsApp / WeChat : 008615127880005

Email : info@aocno.com

Intralox DDS Direct Drive Cooling Tower

AOCNO

Product introduction

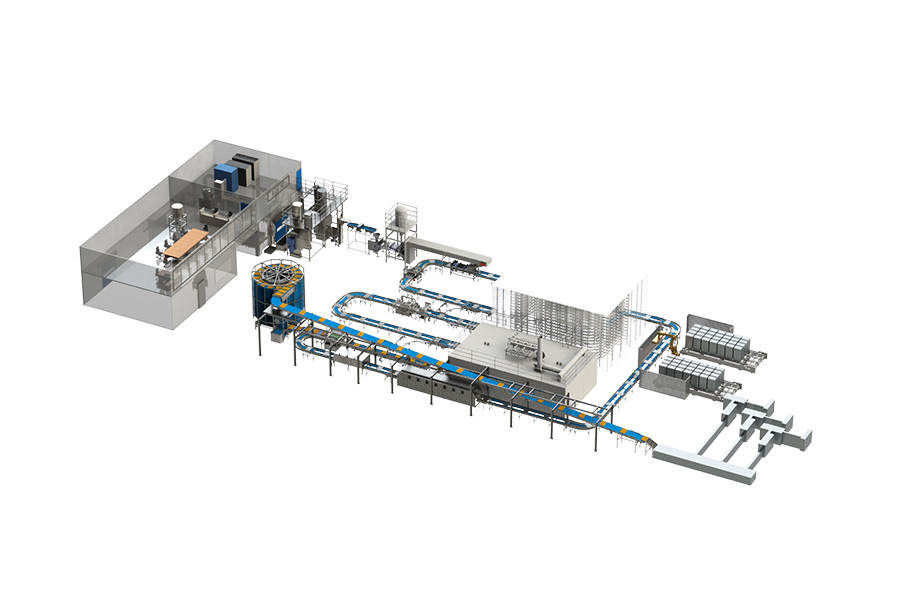

In the world of bakery and food processing, a range of essential bakery equipment in China comes into play. Let's explore some of these remarkable products.

The spiral freezer is a crucial component, rapidly freezing products to preserve their quality and freshness. It ensures efficient and consistent freezing.

The spiral cooler provides a controlled cooling environment for various bakery items, maintaining their integrity.

The bread cooling system is specifically designed to cool bread effectively, ensuring it reaches the right temperature for packaging and storage.

The spiral blast freezer offers intense and rapid freezing capabilities, ideal for high-volume bakery operations.

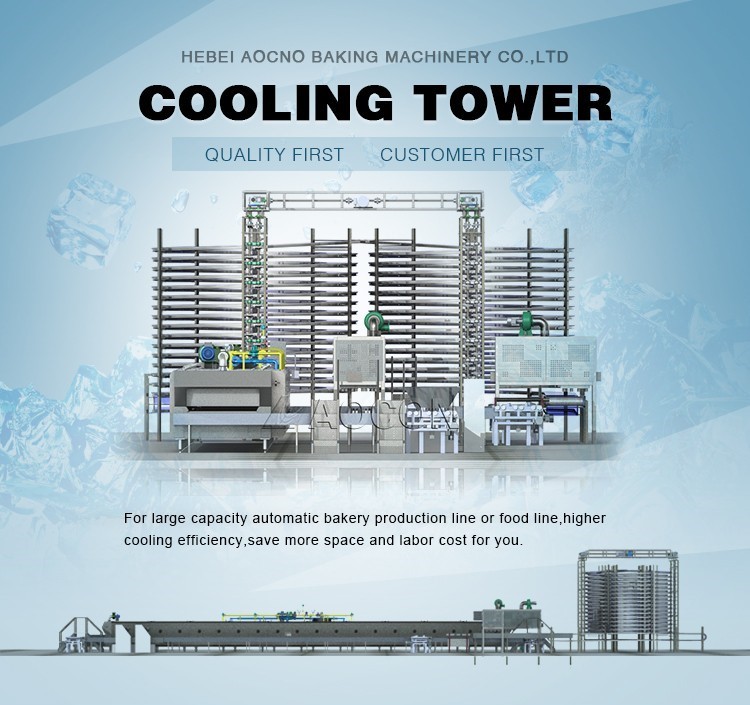

The spiral cooling tower is an efficient solution for cooling processes in the bakery.

The spiral cooler conveyor combines cooling and transportation, streamlining the production line.

When it comes to equipment in the bakery, there is a wide variety to choose from. From basic tools to advanced machinery, it all contributes to the success of the bakery.

The bread cooling tower is an important asset for cooling bread in a controlled manner.

For commercial bakeries, commercial bakery equipment is essential for meeting the demands of large-scale production.

In China, bakery equipment is highly sought-after, with a diverse range available to meet the specific needs of the market.

And for those looking to invest in industrial bakery equipment for sale, there are numerous options to explore, enabling them to expand or upgrade their operations.

These products, along with proper expertise and management, play a vital role in delivering high-quality bakery products to consumers. Whether it's a small local bakery or an industrial-scale facility, the right equipment in bakery is key to success in the bakery industry.

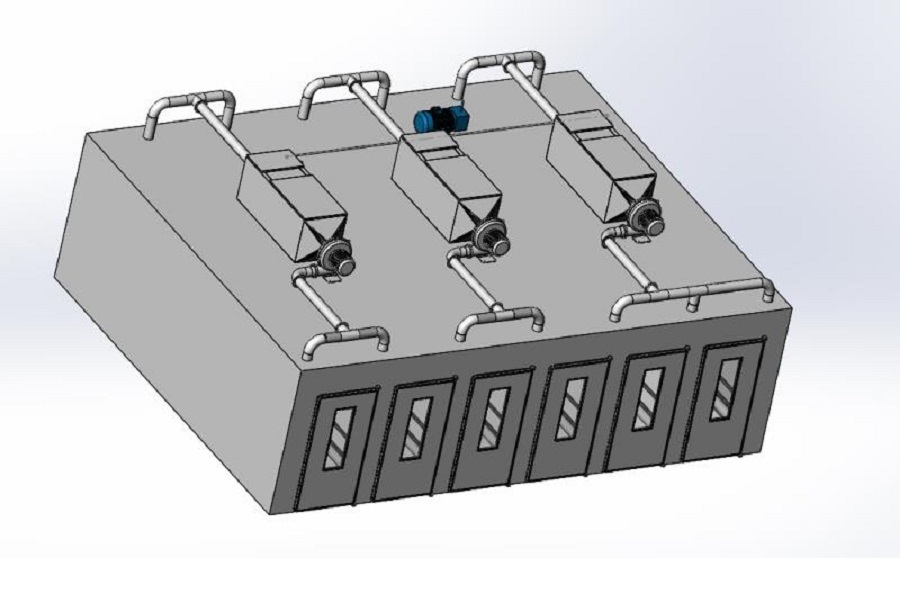

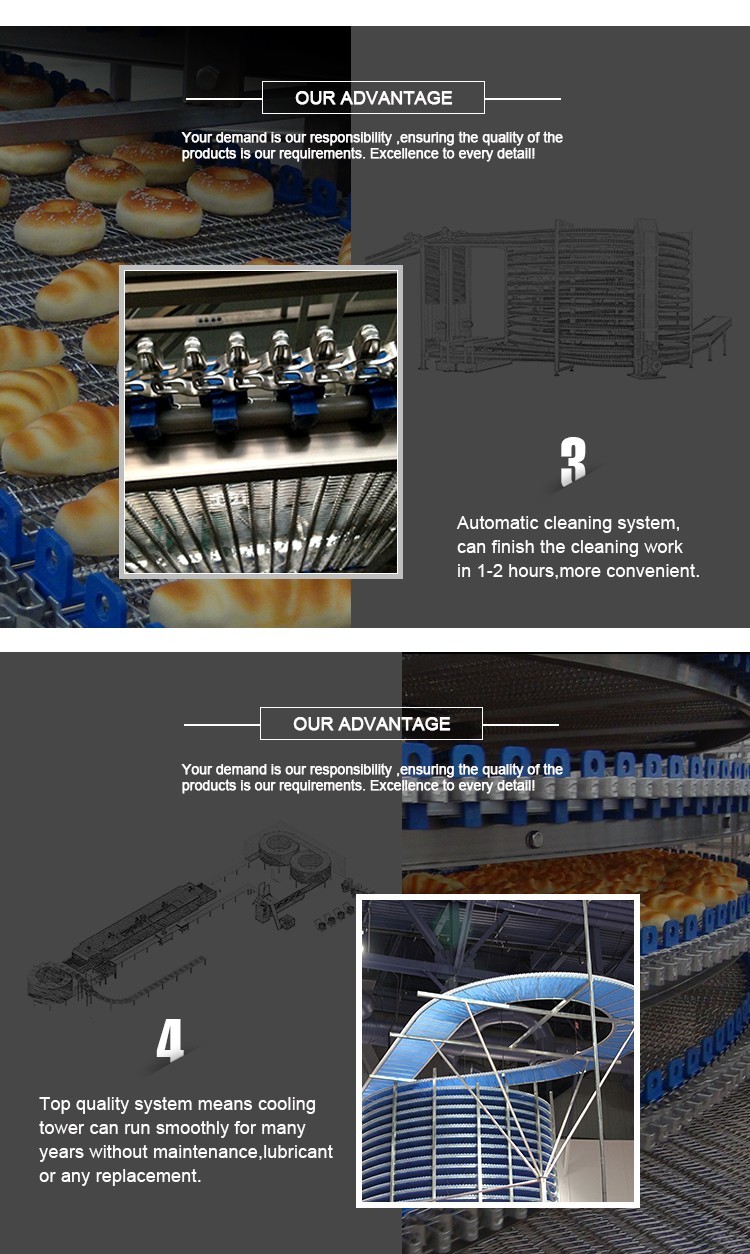

By drastically reducing belt tension and total system stress,DirectDrive Structure-Supported spiral ensure better system performance,reduced downtime,and substantially longer life.

1. Eliminates transmission direction of product related to overdrive. Increases product load capacity,allowing maximum throughout.

2. Reduced product imprints,reducing product losses caused by adhesion by up to 80%,minimizing costly unexpected downtime.

3. Low tension patented technology can ensure that the mesh belt is always in a low tension state,not only preventing the occurrence of turning over,but also greatly extending the service life of the mesh belt.

4. Eliminate black spots and powder generated by metal mesh belts,and completely eliminate food safety hazards caused by metal mesh belts.

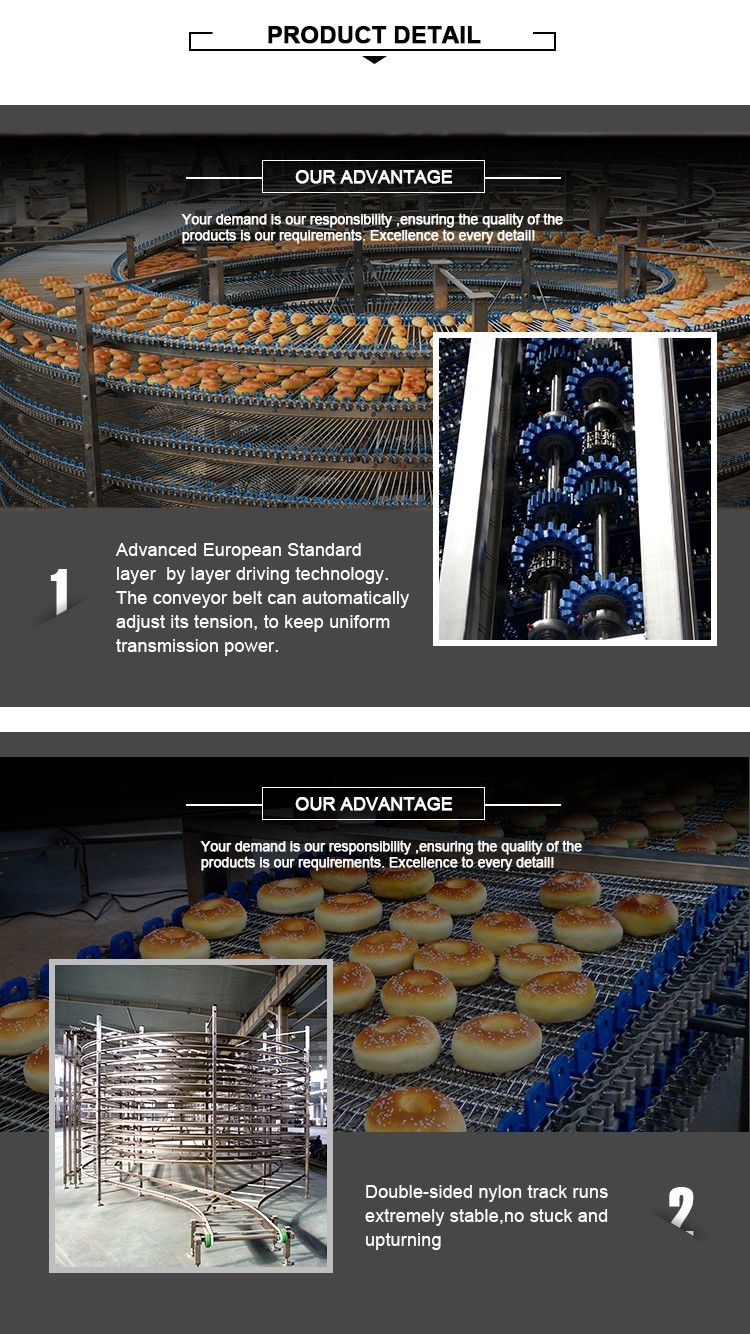

The sanitary and space-saving design of Intertelo directdrive stackers is the ideal solution for smaller products in spiral transfer applications where air flow control is critical, such as freezing and proofing.

The DirectDrive Stacker's belt supports its own weight on the inner and outer edges, removing the need for a traditional carry method. This allows for twice the amount of belting-within the same vertical space, as a structure-supported spiral conveyor.

Key benefits:

Hygienic design cleans easily,efficiently,and thoroughly

Optimal freezing efficiency ,use horizontal airflow

More layers in a small vertical space

Simplified maintenance and cleaning procedures

Lower total cost of ownership compared to traditional self-stackers

Product catalogue

AOCNO 2024 product catalogue

2024/06/20

File format:

File size:

2.3MB

Company workshop

ONLINE CONSULTING