Welcome To Know Our Products, We Can Offer You High Quality Products!

WhatsApp / WeChat : 008615127880005

Email : info@aocno.com

Intermediate Proofer

AOCNO

Product introduction

Function: The dough with high tension and elasticity after being rounded is relaxed and relaxed after proof, which is beneficial for subsequent pressing operations; Yeast produces gas, adjusts the extension direction of the gluten to make it extend in a directional manner, and does not damage the tissue state of the dough during pressing, while also enhancing its gas holding capacity; Make the surface of the dough smooth, enhance its air holding capacity, and prevent it from adhering to the rollers of the molding machine, making it easy to form and operate; The process is usually do in the intermediate proofer.

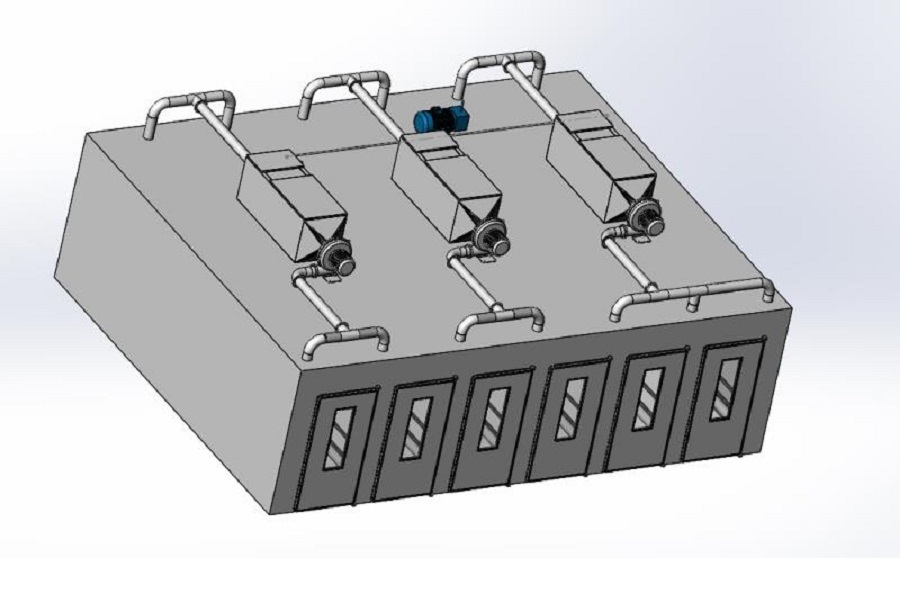

Cradle style intermediate proofer characteristic:

1. Including automatic loading machine

2. Teflon bags that prevent dough adhesion

3. Stainless steel body

4. Siemens PLC Touch Screen

5. Settable proofing time

6. The dough is counted by sensors

7. Conveyor unloading system controlled by photoelectric sensors

Cradle style intermediate proofer

Dough range: 50-1500g

Time:3-10 minutes

Production:1000-3600 pcs/hour

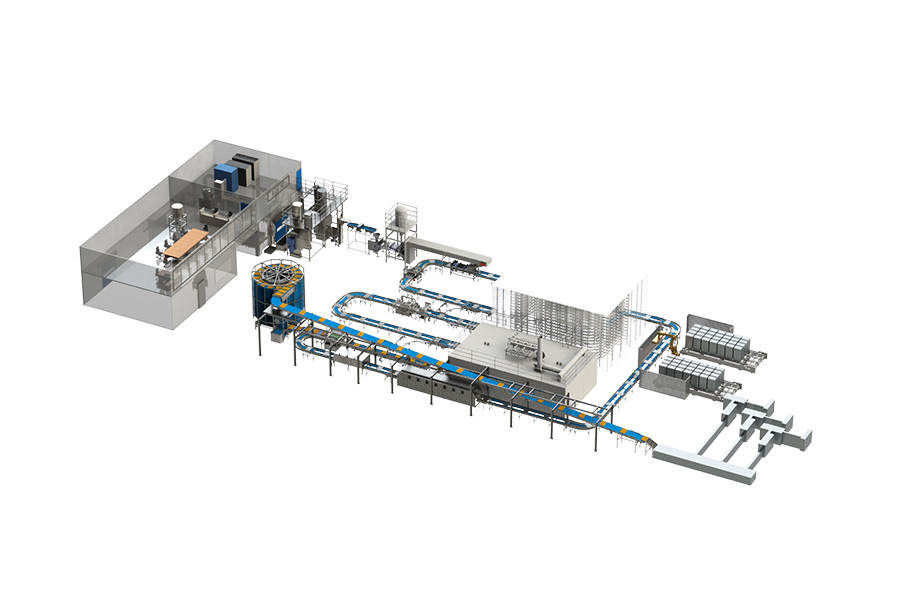

Spiral style intermediate proofer characteristic:

1.Suitable for industrial production with larger output

2.POM spiral conveyor belt to prevent dough adhesion

3. Stainless steel body

4. Siemens PLC Touch Screen

5. Settable proof time

6. The dough is counted by sensors

7. Smoother production process

Spiral type intermediate proofer

Dough range 50-1500g

Time: 3-10 minutes

Production: 1000-3600 pcs/hour

Product catalogue

AOCNO 2024 product catalogue

2024/06/20

File format:

File size:

2.3MB

Company workshop

ONLINE CONSULTING