Welcome To Know Our Products, We Can Offer You High Quality Products!

WhatsApp / WeChat : 008615127880005

Email : info@aocno.com

The Ultimate Guide to Baking Machinery: Enhancing Your Food Production Efficiency

2025-02-08

Baking machinery plays a pivotal role in the food processing industry, specifically in the preparation and production of baked goods. By understanding the various types of baking equipment and their functions, manufacturers can optimize their processes and ensure consistent product quality. This article delves into the key components, operational considerations, and maintenance practices surroundi

Baking machinery plays a pivotal role in the food processing industry, specifically in the preparation and production of baked goods. By understanding the various types of baking equipment and their functions, manufacturers can optimize their processes and ensure consistent product quality. This article delves into the key components, operational considerations, and maintenance practices surrounding baking machinery.

First, it is crucial to identify the types of baking machinery available. Common equipment includes ovens, mixers, proofers, and cooling systems. Ovens come in various configurations such as convection, deck, and rotary, each serving different production needs. Mixers, essential for combining ingredients, also vary in design, from planetary mixers for smaller batches to spiral mixers for high-volume production.

When selecting baking machinery, factors such as production capacity, energy efficiency, and ease of operation should be considered. The right choice not only enhances productivity but also reduces energy consumption, contributing to cost savings in the long run. Furthermore, the integration of technology in baking machinery allows for better monitoring and control of the baking process, ensuring that products are baked to perfection.

Operating baking machinery involves adhering to safety and operational protocols. Proper training for staff is essential to minimize the risk of accidents and ensure efficient operation. This includes understanding the machinery's features, troubleshooting minor issues, and recognizing when to call for professional maintenance. Regular training sessions can significantly enhance the skills of the workforce, leading to higher productivity.

Maintenance is another critical aspect of managing baking machinery. Regular cleaning, inspection, and servicing help extend the lifespan of the equipment and maintain optimal performance. A well-maintained machine not only operates more efficiently but also produces goods with consistent quality. It is advisable to create a maintenance schedule that includes daily, weekly, and monthly checks, ensuring that any potential issues are addressed promptly.

In conclusion, investing in the right baking machinery is a significant step toward improving food production efficiency. By understanding the types of equipment available, adhering to safe operating practices, and implementing a thorough maintenance plan, businesses in the food processing industry can enhance their productivity and maintain high-quality standards. Embracing modern technology and continuous staff training will further ensure that your baking operations remain competitive in this ever-evolving market.

First, it is crucial to identify the types of baking machinery available. Common equipment includes ovens, mixers, proofers, and cooling systems. Ovens come in various configurations such as convection, deck, and rotary, each serving different production needs. Mixers, essential for combining ingredients, also vary in design, from planetary mixers for smaller batches to spiral mixers for high-volume production.

When selecting baking machinery, factors such as production capacity, energy efficiency, and ease of operation should be considered. The right choice not only enhances productivity but also reduces energy consumption, contributing to cost savings in the long run. Furthermore, the integration of technology in baking machinery allows for better monitoring and control of the baking process, ensuring that products are baked to perfection.

Operating baking machinery involves adhering to safety and operational protocols. Proper training for staff is essential to minimize the risk of accidents and ensure efficient operation. This includes understanding the machinery's features, troubleshooting minor issues, and recognizing when to call for professional maintenance. Regular training sessions can significantly enhance the skills of the workforce, leading to higher productivity.

Maintenance is another critical aspect of managing baking machinery. Regular cleaning, inspection, and servicing help extend the lifespan of the equipment and maintain optimal performance. A well-maintained machine not only operates more efficiently but also produces goods with consistent quality. It is advisable to create a maintenance schedule that includes daily, weekly, and monthly checks, ensuring that any potential issues are addressed promptly.

In conclusion, investing in the right baking machinery is a significant step toward improving food production efficiency. By understanding the types of equipment available, adhering to safe operating practices, and implementing a thorough maintenance plan, businesses in the food processing industry can enhance their productivity and maintain high-quality standards. Embracing modern technology and continuous staff training will further ensure that your baking operations remain competitive in this ever-evolving market.

keywords:

RELEVANT INFORMATION

Understanding Tunnel Ovens: The Backbone of Efficient Industrial Baking

2025-04-29

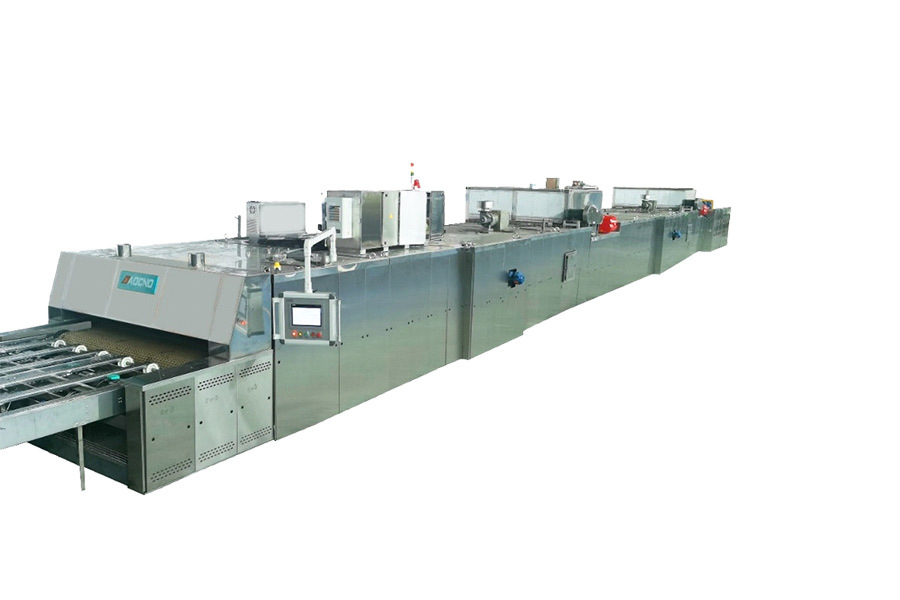

Tunnel ovens are specialized industrial baking devices designed to streamline the production process for a variety of baked goods. Unlike traditional ovens, which typically require manual loading and unloading, tunnel ovens utilize a continuous conveyor belt system that allows products to move through the oven in a steady stream.

Mastering the Art of Baking: Essential Tips for Your New Oven

2025-04-24

Baking is both a science and an art, and mastering it can transform your culinary skills. Whether you are a novice baker or have some experience under your belt, understanding how to effectively use your new oven is crucial for achieving perfect results.

The Essential Guide to Spiral Freezers in Industrial Refrigeration

2025-04-19

Spiral freezers are a critical component in the industrial refrigeration landscape, particularly for businesses involved in the freezing of food products. These innovative machines offer a unique approach to freezing, utilizing a continuous belt system that efficiently transports products through a spiraling pathway.