Welcome To Know Our Products, We Can Offer You High Quality Products!

WhatsApp / WeChat : 008615127880005

Email : info@aocno.com

Enhancing Efficiency: Modern Bakery Equipment Solutions for Optimal Production

2025-02-13

Enhancing Efficiency: Modern Bakery Equipment Solutions

Introduction: The Need for Efficiency in Bakery Operations

In today’s competitive food industry, **bakery businesses** are under constant pressure to improve efficiency while maintaining quality. The rise of consumer demand for fresh and innovative baked goods calls for advancements in **bakery equipment**. Modern bakery equipment solutions n

Enhancing Efficiency: Modern Bakery Equipment Solutions

Introduction: The Need for Efficiency in Bakery Operations

In today’s competitive food industry, **bakery businesses** are under constant pressure to improve efficiency while maintaining quality. The rise of consumer demand for fresh and innovative baked goods calls for advancements in **bakery equipment**. Modern bakery equipment solutions not only streamline production but also enhance the overall baking process, allowing businesses to meet customer expectations effectively.

Understanding Modern Bakery Equipment

Modern bakery equipment encompasses a variety of machines and tools designed to automate, streamline, and enhance the processes involved in baking. From mixing and baking to packaging and distribution, innovations in equipment can lead to significant improvements in efficiency.

The Role of Automation in Bakeries

Automation is a game-changer in the bakery industry. It reduces manual labor, minimizes human error, and speeds up production times. Here are some key areas where automation plays a crucial role:

1. Mixing and Dough Preparation

Automated mixers and dough rollers provide uniform mixing and consistent dough quality, ensuring that every batch meets the required standards. Advanced models even allow for precise control over mixing times and speeds, which can significantly affect the final product.

2. Baking Ovens

Modern baking ovens, such as convection and rotary ovens, offer enhanced heat distribution and energy efficiency. These ovens can be programmed for specific baking times and temperatures, resulting in uniform baking and reduced energy costs.

3. Proofing and Refrigeration Systems

Efficient proofing cabinets and refrigeration units are essential for maintaining optimal dough quality. These systems create controlled environments that promote appropriate fermentation and fermentation times, enhancing flavor and texture.

Choosing the Right Bakery Equipment

Selecting the appropriate equipment for your bakery depends on several factors, including production volume, product variety, and available space. Below are some considerations to keep in mind.

1. Assess Your Production Needs

Understanding your production needs is the first step toward selecting the right equipment. Analyze your current production volume and forecast future growth to ensure that your equipment can keep pace with demand.

2. Evaluate Space and Workflow

Space is often a limiting factor in bakery operations. Consider the layout of your bakery to ensure that the equipment you choose fits well and allows for a smooth workflow. Efficient layouts reduce bottlenecks and improve overall productivity.

3. Research Equipment Options

Investing in the latest technology can yield substantial benefits. Research different brands and models to find equipment with features that align with your bakery's goals. Look for energy-efficient options that can lower operational costs while maintaining performance.

Innovative Equipment Solutions for Bakeries

Several innovative equipment solutions are currently transforming the bakery industry. Incorporating these technologies can significantly enhance efficiency and production capabilities.

1. High-Speed Mixers

High-speed mixers are designed to handle larger batches of dough while ensuring consistent quality. These mixers can reduce mixing time by up to 50%, enabling bakeries to produce more in less time without sacrificing quality.

2. Automated Depositors

Automated depositors simplify the process of portioning dough and batter. By ensuring precise quantities, these machines reduce waste and labor costs while enhancing product consistency.

3. Multi-Functional Ovens

Multi-functional ovens combine baking, steaming, and proofing capabilities in one machine. These ovens offer flexibility in baking various products, from artisan bread to delicate pastries, all while conserving energy and space.

4. Slicing and Packaging Machines

Automated slicing and packaging machines streamline the post-baking process. They ensure uniform slices and efficient packaging, reducing labor costs and improving product presentation.

5. Digital Monitoring Systems

Implementing digital monitoring systems allows bakers to track production metrics in real-time. These systems can identify inefficiencies in the baking process, enabling continuous improvement and enhanced decision-making.

Integrating Technology into Bakery Operations

Embracing technology is essential for modern bakeries looking to enhance efficiency. Here are some key areas where technology can make a significant impact.

1. Inventory Management Systems

Effective inventory management is critical in minimizing waste and managing costs. Advanced systems allow bakeries to track ingredient usage, monitor stock levels, and automate reordering processes, ensuring that you always have the necessary supplies on hand.

2. Point of Sale (POS) Systems

Modern POS systems provide more than just transaction processing. They offer insights into sales trends, customer preferences, and inventory management, empowering bakeries to make informed decisions that can enhance profitability.

3. Online Ordering and Delivery Platforms

As consumer habits shift toward online shopping, bakeries must adapt by offering online ordering and delivery options. Integrated platforms streamline order management and enhance customer satisfaction by providing a seamless purchasing experience.

Best Practices for Enhancing Bakery Efficiency

Efficient bakery operations require more than just investing in equipment. Implementing best practices can help maximize the benefits of modern bakery solutions.

1. Train Your Staff

Proper training ensures that staff members are familiar with the equipment and processes. Regular training sessions can improve productivity, reduce downtime, and enhance the overall quality of baked goods.

2. Maintain Equipment Regularly

Regular maintenance of bakery equipment is essential for preventing breakdowns and prolonging lifespan. Implement a maintenance schedule to perform routine checks and keep equipment in optimal working condition.

3. Foster a Culture of Continuous Improvement

Encouraging feedback from staff can yield valuable insights into areas that need improvement. By fostering a culture of continuous improvement, bakeries can adapt to changing needs and enhance overall efficiency.

4. Optimize Production Scheduling

Utilizing production scheduling software can help bakeries maximize operational efficiency. By analyzing data to anticipate peak times and adjust schedules accordingly, bakeries can ensure that production meets demand without overextending resources.

Frequently Asked Questions (FAQs)

1. What are the benefits of modern bakery equipment?

Modern bakery equipment improves efficiency, reduces labor costs, enhances product quality, and increases production capacity.

2. How do I choose the right bakery equipment for my business?

Assess your production needs, evaluate available space, and research equipment options that align with your baking goals.

3. Can automation really improve bakery operations?

Yes, automation minimizes manual labor, reduces errors, and speeds up production, leading to increased efficiency.

4. What types of advanced baking ovens are available?

Convection ovens, rotary ovens, and multi-functional ovens are some examples of advanced baking ovens offering enhanced capabilities.

5. How can I assess the efficiency of my bakery operations?

Implement digital monitoring systems and track production metrics to identify areas for improvement and optimize efficiency.

Conclusion: The Future of Bakery Operations

Modern bakery equipment solutions present significant opportunities for enhancing efficiency in bakery operations. By embracing automation, investing in innovative technologies, and implementing best practices, bakeries can achieve optimal production levels while maintaining high-quality standards. As the industry continues to evolve, staying ahead of equipment trends and technological advancements will be crucial for success. By making informed decisions today, bakeries can shape a prosperous future and satisfy the ever-growing demand for delicious baked goods.

keywords:

RELEVANT INFORMATION

Understanding Tunnel Ovens: The Backbone of Efficient Industrial Baking

2025-04-29

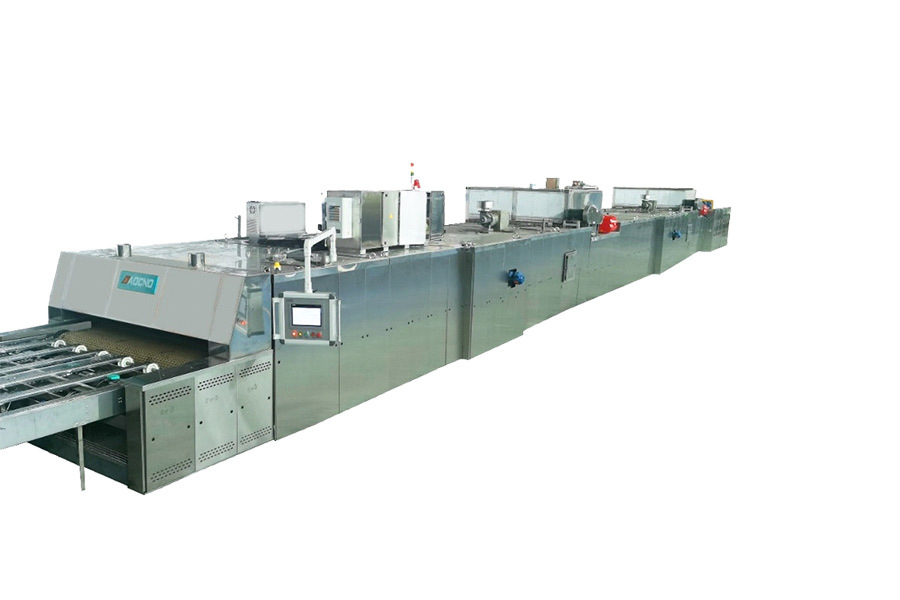

Tunnel ovens are specialized industrial baking devices designed to streamline the production process for a variety of baked goods. Unlike traditional ovens, which typically require manual loading and unloading, tunnel ovens utilize a continuous conveyor belt system that allows products to move through the oven in a steady stream.

Mastering the Art of Baking: Essential Tips for Your New Oven

2025-04-24

Baking is both a science and an art, and mastering it can transform your culinary skills. Whether you are a novice baker or have some experience under your belt, understanding how to effectively use your new oven is crucial for achieving perfect results.

The Essential Guide to Spiral Freezers in Industrial Refrigeration

2025-04-19

Spiral freezers are a critical component in the industrial refrigeration landscape, particularly for businesses involved in the freezing of food products. These innovative machines offer a unique approach to freezing, utilizing a continuous belt system that efficiently transports products through a spiraling pathway.