Welcome To Know Our Products, We Can Offer You High Quality Products!

WhatsApp / WeChat : 008615127880005

Email : info@aocno.com

Optimizing Bakery Operations: Must-Have Machinery for Success

2025-02-03

Introduction

In the fast-paced world of baking, efficiency and quality are paramount. **Optimizing bakery operations** is essential for any business aiming to thrive in a competitive market. With the right machinery, bakeries can streamline processes, reduce labor costs, and enhance product consistency. This article delves into the must-have machinery for successful bakery operations, highlighting how each piece of equipment plays a crucial role in the daily workings of a bakery.

The Importance of Optimizing Bakery Operations

Optimizing bakery operations is more than just a trend; it’s a necessity for sustainability and profitability. As consumer preferences evolve, bakeries must adapt to meet demands for quality, variety, and speed.

**Key considerations include:**

- **Quality Control:** Consistent quality in baked goods is vital for customer satisfaction. The right machinery helps maintain uniformity in products.

- **Efficiency:** Automating processes reduces the time spent on manual tasks, allowing bakers to focus on creativity and product development.

- **Cost Effectiveness:** Investing in modern machinery can lead to significant cost savings over time through reduced waste and labor efficiency.

Essential Machinery for Bakery Success

The backbone of any successful bakery lies in its equipment. Below, we outline the essential machinery that every bakery should consider.

Industrial Mixers

Industrial mixers are foundational to any bakery operation. They ensure consistent blending of ingredients, essential for the quality of doughs, batters, and fillings.

**Key features to look for in mixers include:**

- **Variable Speed Settings:** Allows for versatile mixing techniques, from gentle folding to vigorous whipping.

- **Capacity Options:** Choose a mixer that meets your production volume needs without compromising on quality.

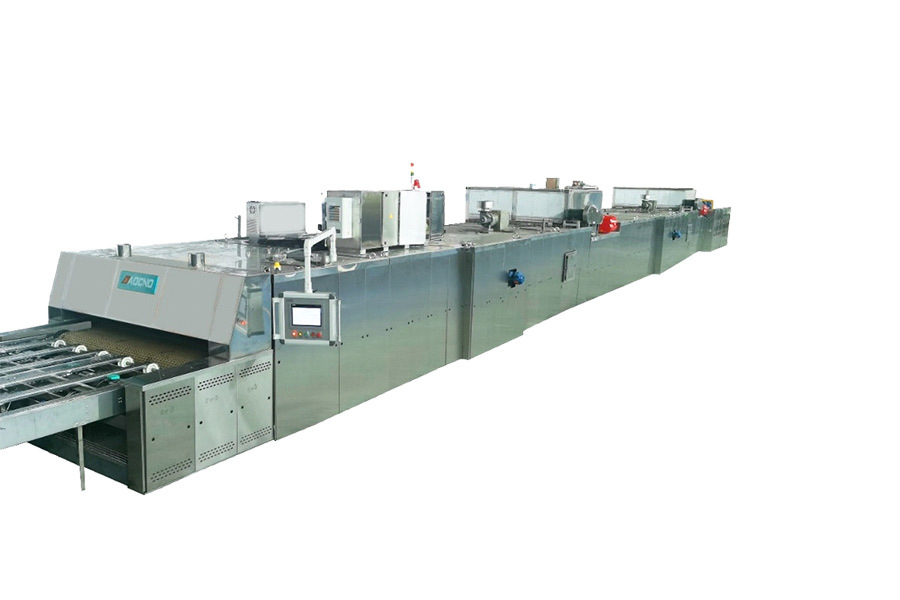

Commercial Ovens

The oven is arguably the heart of the bakery. **Selecting the right type of oven** can make a significant difference in baking quality and efficiency.

**Types of ovens include:**

- **Convection Ovens:** Use fans to circulate hot air, ensuring even baking and reducing cooking times.

- **Deck Ovens:** Provide a traditional baking environment ideal for artisanal breads and pastries.

Proofers and Retarders

Proofers and retarders are essential for controlling fermentation and proofing processes. They create the perfect environment for yeast development, impacting the final product's texture and flavor.

**Key benefits include:**

- **Temperature and Humidity Control:** Ensures optimal conditions for dough to rise, leading to superior baked goods.

- **Flexibility:** Retarders allow bakers to slow down fermentation, providing flexibility in baking schedules.

Bread Slicers

For bakeries that produce bread, **bread slicers** are indispensable. They offer consistent slicing, which not only enhances customer experience but also provides convenience for packaging and selling.

**Considerations for bread slicers:**

- **Adjustable Blade Settings:** Different types of bread require different slice thicknesses.

- **Safety Features:** Look for slicers with safety guards and automatic shut-off mechanisms.

Packaging Machines

Packaging is crucial for preserving freshness and extending shelf life. **Automated packaging machines** help streamline the process, ensuring that products are sealed efficiently and hygienically.

**Key packaging options include:**

- **Flow Wrap Machines:** Ideal for wrapping individual items quickly.

- **Vacuum Sealers:** Perfect for preserving freshness in baked goods.

Benefits of Modern Bakery Machinery

Investing in modern bakery machinery offers numerous benefits that contribute to overall operational success.

**Key advantages include:**

- **Increased Production Capacity:** Modern machines enable higher output levels, meeting growing demand without sacrificing quality.

- **Consistency:** Automated processes reduce human error, ensuring that every batch meets quality standards.

- **Enhanced Safety:** Modern equipment often features advanced safety mechanisms, reducing the risk of accidents in the workplace.

Maintenance Tips for Bakery Machinery

To ensure the longevity and efficacy of bakery machinery, proper maintenance is essential.

**Regular maintenance practices include:**

- **Routine Inspections:** Check equipment regularly for wear and tear, addressing any issues before they escalate.

- **Cleaning Protocols:** Establish a cleaning schedule to maintain hygiene standards and prevent contamination.

- **Professional Servicing:** Engage professional technicians for complex repairs or servicing to ensure optimal performance.

Choosing the Right Machinery for Your Bakery

Selecting the right machinery is crucial for bakery success. Consider the following factors:

**Key considerations include:**

- **Production Volume:** Assess your output needs to ensure you choose equipment that can handle your demands.

- **Space Constraints:** Evaluate your bakery layout to determine what machinery will fit without hindering workflow.

- **Budget:** Factor in not just the initial cost but also long-term maintenance and operational costs.

The Future of Bakery Operations

As technology continues to evolve, so does the bakery industry. The future will likely see an increased emphasis on automation, sustainability, and innovation.

**Trends to watch include:**

- **Smart Machinery:** Integration of IoT technology for real-time monitoring and adjustments.

- **Sustainable Practices:** Equipment designed for energy efficiency and waste reduction.

FAQs

**Q1: What type of oven is best for artisanal bread production?**

A: Deck ovens are generally preferred for artisanal bread due to their ability to retain heat and moisture.

**Q2: How often should bakery machinery be serviced?**

A: Regular servicing every 6-12 months is recommended, depending on usage and manufacturer guidelines.

**Q3: Can I automate all bakery processes?**

A: While many processes can be automated, some, such as decoration and quality control, may still require manual intervention.

**Q4: What is the average lifespan of bakery machinery?**

A: With proper maintenance, most bakery machinery can last anywhere from 10 to 20 years.

**Q5: Are there financing options available for purchasing bakery equipment?**

A: Yes, many equipment suppliers offer financing options, leases, or payment plans to help manage costs.

Conclusion

Optimizing bakery operations through the right machinery is a game-changer for any bakery looking to enhance efficiency and product quality. By investing in essential equipment such as industrial mixers, commercial ovens, proofers, and packaging machines, bakers can streamline their processes, ensure consistency, and ultimately increase profitability. As the industry continues to evolve, staying ahead of trends and maintaining equipment will be key to long-term success. Whether you are starting a new bakery or looking to upgrade existing operations, understanding the importance of machinery is essential for achieving your business goals.

keywords:

RELEVANT INFORMATION

Understanding Tunnel Ovens: The Backbone of Efficient Industrial Baking

2025-04-29

Mastering the Art of Baking: Essential Tips for Your New Oven

2025-04-24

The Essential Guide to Spiral Freezers in Industrial Refrigeration

2025-04-19