Welcome To Know Our Products, We Can Offer You High Quality Products!

WhatsApp / WeChat : 008615127880005

Email : info@aocno.com

Optimizing Your Bread Production Line for Maximum Efficiency

2025-05-29

In the realm of kitchen appliance manufacturing, particularly for products like toasters and bread machines, understanding the intricacies of a bread production line is crucial. A bread production line encompasses all stages of bread manufacturing—from mixing ingredients to the final packaging. Streamlining each stage not only enhances productivity but also ensures consistent quality, which is essential for consumer satisfaction.

The first step in an efficient bread production line is the formulation and mixing of dough. Modern mixers, equipped with programmable controls, can precisely measure and mix ingredients to ensure uniformity. This consistency is vital for producing high-quality bread that meets consumer expectations. Additionally, the incorporation of automated systems can reduce labor costs and minimize human error during this phase.

Once the dough is prepared, the next critical component is the molding and proofing process. Utilizing advanced molding machines enables manufacturers to produce various shapes and sizes of bread, catering to diverse consumer preferences. Furthermore, an efficient proofing system is essential for allowing the dough to rise correctly. Temperature and humidity control are vital during this phase; thus, integrating climate control technology can significantly enhance the fermentation process.

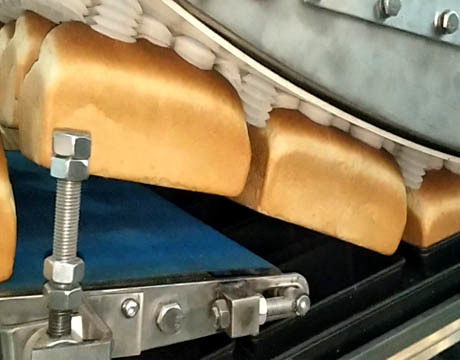

Baking follows proofing, and this is where the type of oven can impact the final product's quality. Conveyor ovens, for instance, maintain consistent temperatures and can accommodate high production rates. By utilizing steam injection technology, manufacturers can create a crusty exterior while maintaining a soft interior, a feature highly sought after by consumers.

After baking, the cooling phase is essential to prevent moisture accumulation, which can lead to spoilage. Implementing a cooling conveyor system ensures that bread is cooled uniformly and efficiently before packaging. This step is crucial, as packaging warm bread can affect its texture and shelf life.

Finally, the packaging stage of the bread production line should not be overlooked. Automated packaging machines can significantly enhance the speed and accuracy of this process. Moreover, using sustainable packaging materials can improve the appeal of the product to environmentally conscious consumers, ultimately enhancing brand reputation.

In conclusion, optimizing a bread production line involves integrating advanced technologies and automated systems across all stages of production. For manufacturers of kitchen appliances like toasters and bread machines, understanding these processes can lead to the development of better products, ultimately benefiting consumers. By focusing on each component of the production line, companies can enhance product quality, increase efficiency, and cater to the evolving demands of the market.

keywords:

RELEVANT INFORMATION

Optimizing Your Bread Production Line for Maximum Efficiency

2025-05-29

Master the Art of Baking with the Right Equipment – Your Comprehensive Guide

2025-05-24

Unlock the Art of Home Baking with a Bread Making Machine

2025-05-19