Welcome To Know Our Products, We Can Offer You High Quality Products!

WhatsApp / WeChat : 008615127880005

Email : info@aocno.com

Streamlining Manufacturing Processes: The Benefits of Spiral Cooling Conveyors

2025-04-14

Introduction to Spiral Cooling Conveyors

In the rapidly evolving landscape of manufacturing, efficiency and product quality are paramount. One innovative solution that has gained traction in recent years is the spiral cooling conveyor. These systems are designed to enhance cooling processes while optimizing space and minimizing energy consumption. This article delves into the mechanics, advantages, and applications of spiral cooling conveyors, aiming to provide a comprehensive understanding of how they can streamline your manufacturing operations.

What Are Spiral Cooling Conveyors?

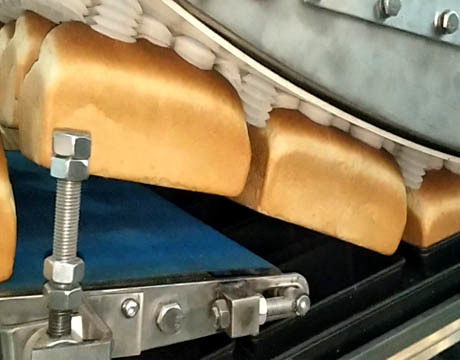

Spiral cooling conveyors are specially designed industrial systems that facilitate the cooling of products as they move through a spiral pathway. Unlike traditional cooling methods that may require extensive floor space and inefficient cooling times, spiral cooling conveyors utilize a compact design that allows for continuous product movement while effectively reducing temperatures. Their innovative structure typically includes a series of spiraling belts or trays that circulate products in a controlled manner, ensuring uniform cooling.

How Do Spiral Cooling Conveyors Work?

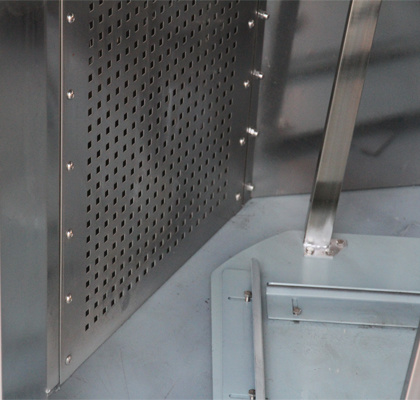

At the core of spiral cooling conveyors is their unique design, which maximizes the surface area for cooling while minimizing the footprint of the equipment. Products are fed onto the conveyor and travel upward in a spiral motion. As they ascend, they are subjected to a controlled cooling airflow, which is often generated by high-efficiency fans strategically placed throughout the system. This cooling method ensures that products are cooled uniformly and efficiently.

The conveyor belt or trays can be customized based on the type of product being cooled, allowing for optimal performance tailored to specific manufacturing needs. The integration of sensors and control systems further enhances the precision of the cooling process, ensuring that products are maintained at desired temperatures before they proceed to subsequent stages of production or packaging.

Key Benefits of Spiral Cooling Conveyors

1. Efficiency Improvements

Implementing spiral cooling conveyors significantly increases manufacturing efficiency. Traditional cooling methods often involve delays and bottlenecks. In contrast, the continuous flow of products through a spiral conveyor minimizes wait times, allowing for a smoother production line. This efficiency translates into higher output rates and reduced labor costs, ultimately enhancing the bottom line.

2. Energy Savings

Energy consumption in manufacturing processes can be a significant cost factor. Spiral cooling conveyors are designed to be energy-efficient, utilizing advanced technology to cool products effectively without excessive energy expenditure. By optimizing airflow and minimizing the required cooling time, manufacturers can achieve substantial savings on energy bills.

3. Product Quality Enhancement

One of the most critical aspects of manufacturing is maintaining product quality. Spiral cooling conveyors provide consistent cooling, which is essential for products that require specific temperature controls to avoid spoilage or deformity. This reliability not only improves the final product but also enhances overall customer satisfaction and brand reputation.

4. Space-Saving Design

In crowded manufacturing facilities, space is often at a premium. The compact design of spiral cooling conveyors allows them to fit into tight production areas without sacrificing performance. Their vertical structure ensures that they occupy less floor space while still accommodating a high throughput of products.

5. Versatility and Customization

Spiral cooling conveyors are incredibly versatile and can be customized to fit various industrial applications. Whether cooling baked goods, plastics, or chemicals, these systems can be tailored to meet the specific needs of different products. Customizations can include adjustable speed settings, varying cooling methods, and the integration of additional features such as automated loading and unloading systems.

Applications of Spiral Cooling Conveyors in Industrial Settings

Spiral cooling conveyors are employed in a wide range of industrial settings, demonstrating their versatility and effectiveness. Common applications include:

- **Food Processing**: In the food industry, spiral cooling conveyors are used for cooling baked goods, chocolates, and other temperature-sensitive items, ensuring they maintain their texture and flavor.

- **Plastics and Packaging**: These conveyors are ideal for cooling plastic parts after molding, helping to maintain their shape and integrity during the cooling process.

- **Pharmaceuticals**: In the pharmaceutical industry, precise temperature control is essential, making spiral cooling conveyors an excellent choice for cooling medications and other sensitive products.

- **Electronics Manufacturing**: For cooling electronic components post-manufacturing, spiral cooling conveyors provide a reliable and efficient solution.

Choosing the Right Spiral Cooling Conveyor for Your Needs

Selecting the appropriate spiral cooling conveyor involves considering several factors to ensure optimal performance and efficiency:

1. **Product Type**: Identify the products you need to cool and their specific requirements. Different materials may require different cooling methods and speeds.

2. **Space Availability**: Assess your facility's layout and determine how much space you can allocate for the conveyor system.

3. **Cooling Requirements**: Understand the temperature specifications needed for your products to select a conveyor that meets those criteria.

4. **Throughput Needs**: Evaluate your production rates to choose a system that can handle the required volume without causing delays.

5. **Customization Options**: Look for vendors that offer customization features to tailor the conveyor to your unique manufacturing processes.

Maintenance and Reliability of Spiral Cooling Conveyors

Maintaining spiral cooling conveyors is crucial for ensuring their longevity and optimal performance. Regular maintenance tasks include:

- **Routine Inspections**: Regularly check for wear and tear on conveyor belts and components to prevent breakdowns.

- **Cleaning**: Keep the system clean, especially in food processing applications, to avoid contamination and ensure compliance with health standards.

- **Lubrication**: Periodically lubricate moving parts to minimize friction and enhance operational efficiency.

- **Monitoring Performance**: Use sensors and monitoring systems to track performance metrics, allowing for timely interventions if issues arise.

By adhering to a diligent maintenance schedule, manufacturers can enhance the reliability of their spiral cooling conveyors, ensuring they continue to operate efficiently for years to come.

Frequently Asked Questions (FAQs)

1. What is the primary purpose of a spiral cooling conveyor?

The primary purpose of a spiral cooling conveyor is to cool products efficiently as they move through a spiraling pathway, optimizing space and reducing cooling times.

2. Can spiral cooling conveyors be customized for specific products?

Yes, spiral cooling conveyors can be tailored to meet the needs of various products, including adjustments in speed, cooling methods, and additional features.

3. How do spiral cooling conveyors improve energy efficiency?

These systems enhance energy efficiency by utilizing advanced technology to optimize airflow and minimize the cooling time required for products.

4. In which industries are spiral cooling conveyors commonly used?

Spiral cooling conveyors are commonly used in food processing, plastics, pharmaceuticals, and electronics manufacturing.

5. What maintenance is required for spiral cooling conveyors?

Routine maintenance tasks include inspections for wear and tear, cleaning, lubrication of moving parts, and monitoring performance metrics.

Conclusion

Integrating spiral cooling conveyors into manufacturing processes offers a range of benefits that can significantly enhance operational efficiency, product quality, and overall profitability. Their innovative design, energy efficiency, and adaptability make them a valuable asset in various industrial applications. By understanding the mechanics and advantages of these systems, manufacturers can make informed decisions that will streamline their production lines and elevate their products in a competitive marketplace. Embracing such technology not only fosters growth but also ensures a commitment to excellence in every product delivered.

keywords:

RELEVANT INFORMATION

Optimizing Your Bread Production Line for Maximum Efficiency

2025-05-29

Master the Art of Baking with the Right Equipment – Your Comprehensive Guide

2025-05-24

Unlock the Art of Home Baking with a Bread Making Machine

2025-05-19