Welcome To Know Our Products, We Can Offer You High Quality Products!

WhatsApp / WeChat : 008615127880005

Email : info@aocno.com

Understanding Spiral Coolers: An Efficient Solution for Industrial Cooling Needs

2025-02-28

---

Spiral coolers are innovative cooling devices commonly used in industrial applications to manage heat transfer effectively. These cooling systems are designed in a spiral configuration, which allows for a compact and efficient cooling process. In this article, we will delve into the functionality, advantages, and applications of spiral coolers, highlighting their critical role in various indus

---

Spiral coolers are innovative cooling devices commonly used in industrial applications to manage heat transfer effectively. These cooling systems are designed in a spiral configuration, which allows for a compact and efficient cooling process. In this article, we will delve into the functionality, advantages, and applications of spiral coolers, highlighting their critical role in various industries.

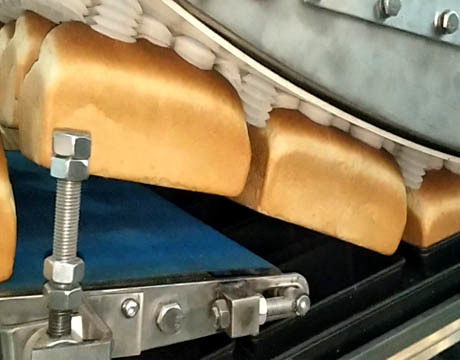

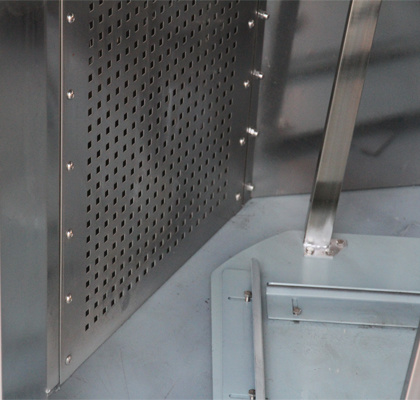

At the core of a spiral cooler is its unique design. The spiral structure maximizes the surface area for heat exchange while minimizing the volume needed for installation. This means that spiral coolers can fit into tight spaces without compromising performance. The design also promotes continuous flow, allowing for efficient cooling as materials move through the system in a helical path. This continuous flow reduces the risk of hot spots, ensuring uniform cooling across the entire process.

Spiral coolers are particularly beneficial in sectors where temperature control is paramount. For instance, in food processing, they are used to cool products rapidly, preserving quality and extending shelf life. In chemical manufacturing, these coolers help maintain optimal reaction temperatures, ensuring safety and efficiency. Additionally, spiral coolers are valuable in HVAC systems, providing effective cooling in commercial buildings.

Another significant advantage of spiral coolers is their energy efficiency. Compared to traditional cooling methods, they require less energy to operate due to their effective heat exchange capabilities. This not only helps reduce operational costs but also aligns with sustainability goals by minimizing energy consumption. Moreover, many spiral coolers are designed to be low-maintenance, which can further decrease downtime and maintenance expenses for industrial operators.

The versatility of spiral coolers extends beyond specific industries. They can accommodate various materials, including liquids, gases, and solids, making them an essential component in many industrial processes. Their adaptability means they can be tailored to meet the specific cooling needs of different applications, ensuring optimal performance across diverse environments.

In conclusion, spiral coolers represent a sophisticated solution for industrial cooling challenges. With their efficient design, energy-saving benefits, and versatility, they play a vital role in enhancing process efficiency in numerous sectors. Whether in food processing, chemical manufacturing, or HVAC systems, spiral coolers are essential devices that contribute to improved operational performance. As industries continue to prioritize efficiency and sustainability, the adoption of advanced cooling technologies like spiral coolers is likely to increase, ensuring a cooler, more efficient future.

Spiral coolers are innovative cooling devices commonly used in industrial applications to manage heat transfer effectively. These cooling systems are designed in a spiral configuration, which allows for a compact and efficient cooling process. In this article, we will delve into the functionality, advantages, and applications of spiral coolers, highlighting their critical role in various industries.

At the core of a spiral cooler is its unique design. The spiral structure maximizes the surface area for heat exchange while minimizing the volume needed for installation. This means that spiral coolers can fit into tight spaces without compromising performance. The design also promotes continuous flow, allowing for efficient cooling as materials move through the system in a helical path. This continuous flow reduces the risk of hot spots, ensuring uniform cooling across the entire process.

Spiral coolers are particularly beneficial in sectors where temperature control is paramount. For instance, in food processing, they are used to cool products rapidly, preserving quality and extending shelf life. In chemical manufacturing, these coolers help maintain optimal reaction temperatures, ensuring safety and efficiency. Additionally, spiral coolers are valuable in HVAC systems, providing effective cooling in commercial buildings.

Another significant advantage of spiral coolers is their energy efficiency. Compared to traditional cooling methods, they require less energy to operate due to their effective heat exchange capabilities. This not only helps reduce operational costs but also aligns with sustainability goals by minimizing energy consumption. Moreover, many spiral coolers are designed to be low-maintenance, which can further decrease downtime and maintenance expenses for industrial operators.

The versatility of spiral coolers extends beyond specific industries. They can accommodate various materials, including liquids, gases, and solids, making them an essential component in many industrial processes. Their adaptability means they can be tailored to meet the specific cooling needs of different applications, ensuring optimal performance across diverse environments.

In conclusion, spiral coolers represent a sophisticated solution for industrial cooling challenges. With their efficient design, energy-saving benefits, and versatility, they play a vital role in enhancing process efficiency in numerous sectors. Whether in food processing, chemical manufacturing, or HVAC systems, spiral coolers are essential devices that contribute to improved operational performance. As industries continue to prioritize efficiency and sustainability, the adoption of advanced cooling technologies like spiral coolers is likely to increase, ensuring a cooler, more efficient future.

keywords:

RELEVANT INFORMATION

Optimizing Your Bread Production Line for Maximum Efficiency

2025-05-29

In the realm of kitchen appliance manufacturing, particularly for products like toasters and bread machines, understanding the intricacies of a bread production line is crucial. A bread production line encompasses all stages of bread manufacturing—from mixing ingredients to the final packaging.

Master the Art of Baking with the Right Equipment – Your Comprehensive Guide

2025-05-24

Baking is both an art and a science, requiring precision, passion, and, most importantly, the right tools. With the proper equipment, anyone can create delightful pastries, breads, and cakes that impress family and friends. This guide will explore the essential baking equipment you need to master the art of baking, including mixers, ovens, and specialty tools.

Unlock the Art of Home Baking with a Bread Making Machine

2025-05-19

When it comes to the convenience of baking fresh bread at home, a bread making machine can be an invaluable addition to your kitchen. These innovative appliances simplify the bread-making process and allow you to enjoy the delightful aroma of freshly baked bread without the hassle of traditional methods.