Welcome To Know Our Products, We Can Offer You High Quality Products!

WhatsApp / WeChat : 008615127880005

Email : info@aocno.com

Automatic Toast Production Line bread production line

Categories:

Product introduction

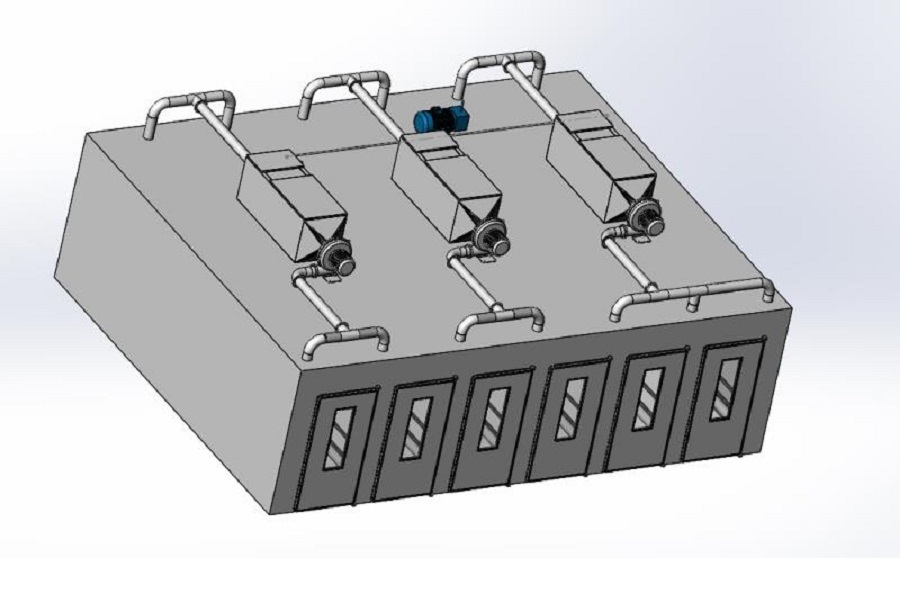

1、Water chiller & auto ingredient system

2、Mixing system

3、Bowl lifter,dough chunker,conveyor

4、Divider

5、Belt frozen rounder

6、Intermediate proofer

7、Toast moulder

8、Panner

9、Auto proofer

10、Auto lidding

11、Tunnel oven

12、Auto lid remover

13、Auto depanner

14、Mold cooling tunnel conveyor

15、Robot pan stacker/ unstakcer system

16、Oil sprayer

17、Spiral cooling tower

18、Lane conveyor

19、Auto slicer

20、Auto bagger

21、Auto clip or twist lock

22、Ink jet printer

23、Metal detector

Production Capacity: 500-5000kg/h,1000-9000 pcs/h

Customized according to customer demand

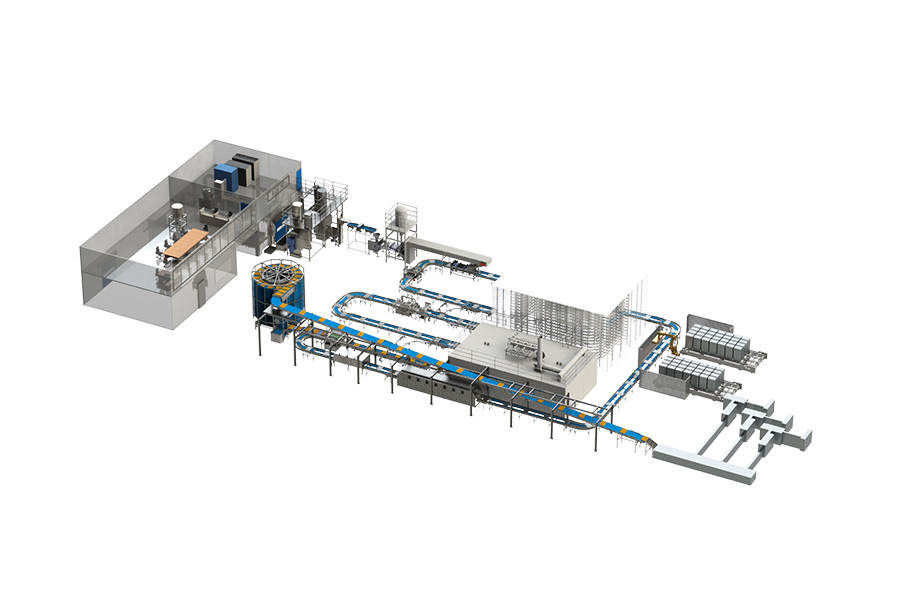

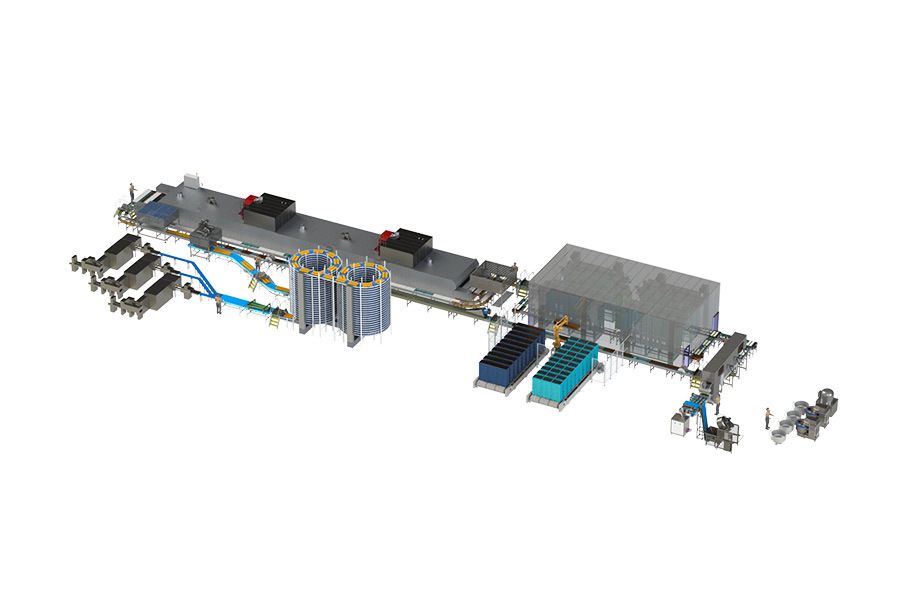

Automatic Toast Production Line

Bread production lines represent the pinnacle of efficiency and innovation in the bread-making industry, offering comprehensive solutions for large-scale bread production. These sophisticated systems integrate advanced technology, precision engineering, and automation to streamline the bread production process from dough preparation to packaging. Let's explore the key features, advantages, and diverse applications of bread production lines.

-

High-Speed Dough Processing: Bread production lines are equipped with high-speed dough processing equipment that efficiently mixes, kneads, and shapes the dough. Automated mixers ensure thorough blending of ingredients, while dough dividers accurately portion the dough for uniformity in size and weight. This high-speed processing capability allows for rapid production rates, catering to the demands of large-scale bakeries and food manufacturing facilities.

-

Customizable Production Parameters: Modern bread production lines offer customizable production parameters to accommodate various bread recipes and specifications. Operators can adjust factors such as dough consistency, proofing time, and baking temperature to achieve desired results and meet specific product requirements. This flexibility enables the production of a diverse range of bread types, from soft sandwich loaves to crusty artisan breads.

-

Efficient Oven Technology: Bread production lines feature advanced oven technology designed for optimal baking performance and energy efficiency. Conveyorized ovens with precise temperature control and airflow management ensure consistent baking results across all bread products. Additionally, modular oven designs allow for easy expansion or reconfiguration to adapt to changing production needs.

-

Integrated Proofing Systems: Integrated proofing systems within bread production lines provide controlled environments for dough fermentation, allowing for optimal dough development and flavor enhancement. Automated proofing chambers maintain ideal temperature and humidity levels to ensure consistent proofing results, resulting in bread with superior texture, flavor, and volume.

-

Automated Packaging Solutions: Bread production lines are equipped with automated packaging solutions that streamline the final stage of the production process. From slicing and bagging to sealing and labeling, these systems ensure efficient packaging of freshly baked bread while maintaining product quality and freshness. Advanced packaging technologies also offer options for customized branding and packaging formats to enhance product presentation and market appeal.

-

Hygiene and Sanitation Standards: Bread production lines adhere to strict hygiene and sanitation standards to ensure the safety and integrity of the final product. Stainless steel construction, smooth surfaces, and sanitary design features minimize the risk of contamination and facilitate easy cleaning and sanitation procedures. Automated cleaning-in-place (CIP) systems further enhance hygiene practices by providing thorough cleaning of equipment components without disassembly.

-

Scalability and Modular Design: Bread production lines are designed with scalability and modular flexibility in mind, allowing for easy expansion or customization to accommodate changing production volumes or product portfolios. Modular equipment configurations enable efficient use of space and resources, optimizing production efficiency and cost-effectiveness for bakery operations of all sizes.

In conclusion, bread production lines represent a paradigm shift in bread manufacturing, offering unmatched efficiency, precision, and versatility for large-scale production environments. With their advanced features, customizable parameters, and integrated solutions, these systems empower bakeries and food manufacturers to meet consumer demand for high-quality bread products while maximizing operational efficiency and profitability. Whether producing traditional bread varieties or innovative specialty products, bread production lines set the standard for excellence in the baking industry.

Product catalogue

AOCNO Catalogue

2022/01/19

File format:

File size:

2.3MB

Company workshop

keywords:

ONLINE CONSULTING