Welcome To Know Our Products, We Can Offer You High Quality Products!

WhatsApp / WeChat : 008615127880005

Email : info@aocno.com

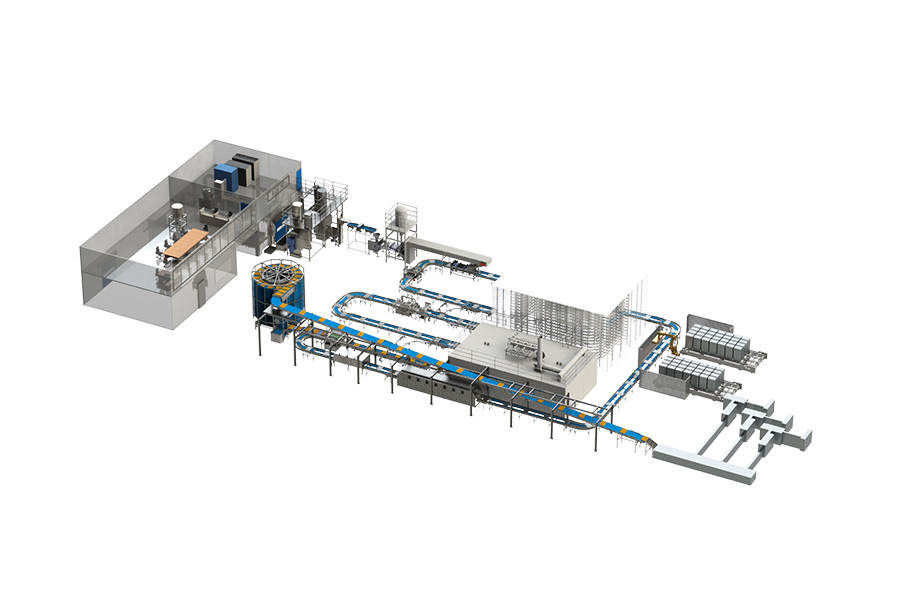

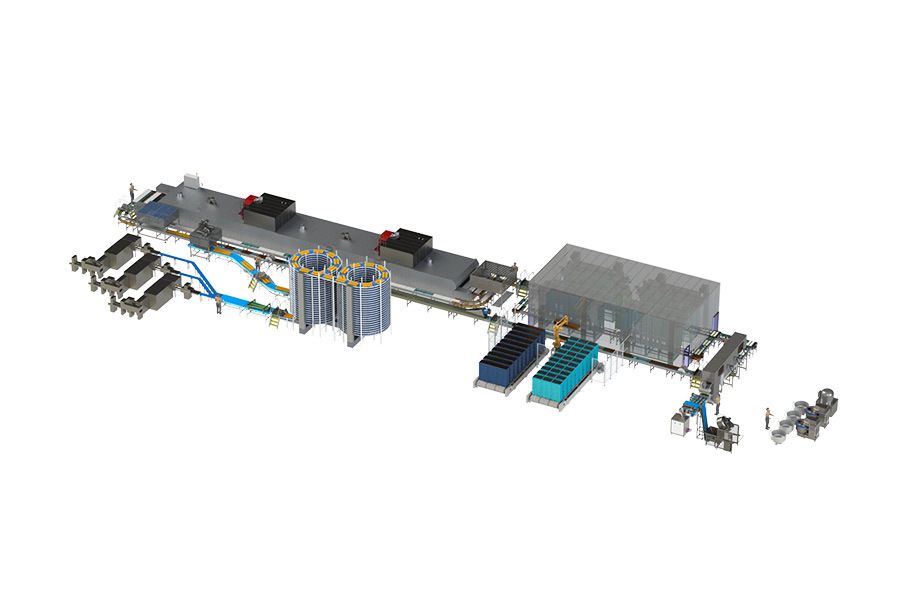

Hamburger Makeup Line equipment for a bakery

Categories:

Product introduction

1. Dough pump

2. Belt conveyor

3. Vector divider

4. Frozen rounder

5. Intermediate proofer

6. Auto moulder

7. Auto panner

8. Servo shaker machine

9. Turning conveyor

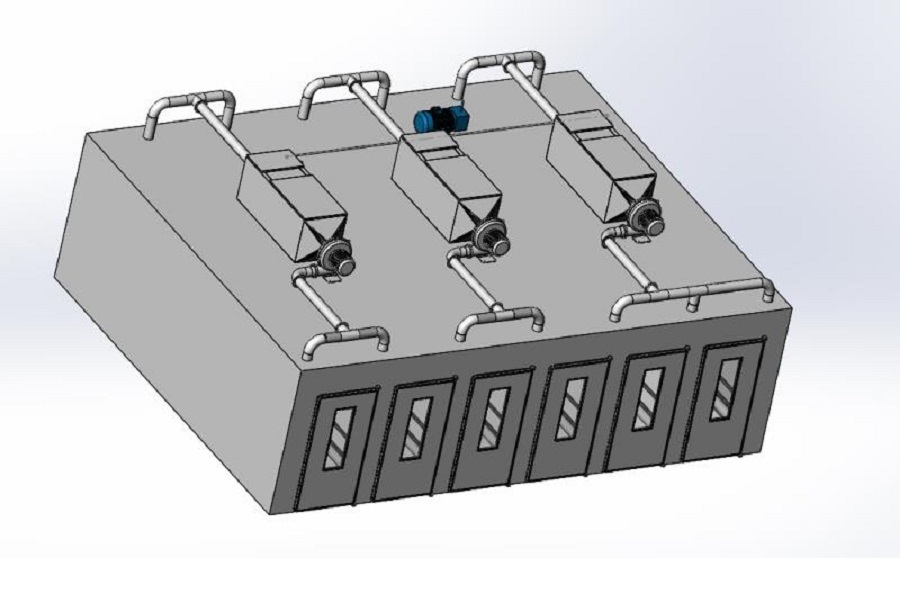

10.Multiple flour recycling machine

Servo weight stabilization system

Stainless steel body

Vector technology enables dough to achieve perfect.

The dividing accuracy error not exceed 1%

|

|

Configuration |

Divider model |

Variable speed range * (pcs/hr.) |

Maximum conveying capacity* |

Cutting range |

Voltage |

Power |

|

Hamburger makeup system |

4 channels

|

VE-24000/4

|

8000-28000

|

1800 kg

|

26-200g |

220V-400V |

22KW |

|

6 channels |

VE-36000/6 |

14000-36000 |

3600 kg |

Hamburger Makeup Line

In the bustling world of baking, having the right equipment for a bakery is crucial to ensure efficient production, consistent quality, and the ability to meet customer demands. From mixers and ovens to dough sheeters and proofing cabinets, innovative bakery equipment has revolutionized the way bakeries operate. Let's explore the key features, advantages, and diverse applications of equipment for a bakery.

-

Efficient Mixing and Dough Preparation: Cutting-edge bakery equipment offers efficient mixing and dough preparation capabilities. High-capacity mixers incorporate advanced technologies to ensure thorough ingredient blending, dough development, and gluten formation. This enables bakeries to achieve consistent dough quality and optimal texture for a wide range of bakery products.

-

Precision Baking with Advanced Ovens: Modern bakery equipment includes advanced ovens that provide precise temperature control, uniform heat distribution, and optimal airflow management. These features result in even baking and consistent product quality across batches. Furthermore, innovative oven designs offer energy-saving features and programmable settings to cater to diverse baking requirements.

-

Versatile Dough Sheeters and Moulders: Dough sheeters and moulders are essential tools in a bakery, enabling efficient and consistent dough shaping for various products. These versatile machines can handle a wide range of dough types, sizes, and shapes, including sheets for pastries, rolls for bread, and more. They ensure uniform thickness, precise rolling, and seamless production processes.

-

Optimized Dough Proofing: Bakery equipment includes specialized proofing cabinets designed to create optimal conditions for dough fermentation. These cabinets offer precise temperature and humidity control, ensuring consistent proofing results regardless of ambient conditions. Proper dough proofing enhances flavor development, texture, and volume in the final baked goods.

-

Customizable Panning and Depositing Solutions: Panning and depositing equipment streamline the process of portioning and shaping dough or batter into molds or trays. These machines offer flexibility and precision, allowing bakeries to create a variety of product sizes and shapes, from individual rolls and buns to specialty breads and pastries. Customizable options enable easy adaptation to changing product trends and customer preferences.

-

Automated Slicing and Packaging: Bakery equipment features automated slicing and packaging solutions that enhance efficiency and product presentation. These systems ensure consistent slicing thickness, reducing waste and enhancing product uniformity. Integrated packaging machines handle the efficient sealing, labeling, and packaging of bakery products, optimizing shelf-life and preserving product freshness.

-

Hygiene and Safety Standards: Bakery equipment is designed with hygiene and safety in mind, complying with strict industry standards. Stainless steel construction, easy-to-clean surfaces, and sanitary design features minimize the risk of contamination and facilitate thorough cleaning and sanitation procedures. This ensures the production of safe and high-quality bakery products.

-

Scalability and Customization Options: Equipment for a bakery is available in scalable configurations, allowing bakeries to expand their operations as per demand. Modular designs offer flexibility in adapting to changing production volumes or diversifying product offerings. Customization options enable bakeries to tailor equipment to their specific needs, ensuring optimal performance and efficiency.

In conclusion, innovative equipment for a bakery has transformed the way bakeries operate, streamlining production processes, ensuring consistent quality, and maximizing efficiency. With their advanced features, versatility, and adherence to hygiene and safety standards, these equipment solutions empower bakeries to meet customer demands, explore new product possibilities, and thrive in the competitive baking industry. Whether it's a small artisanal bakery or a large-scale industrial facility, investing in the right bakery equipment is key to achieving success and excellence in the art of baking.

Product catalogue

AOCNO Catalogue

2022/01/19

File format:

File size:

2.3MB

Company workshop

keywords:

ONLINE CONSULTING